In the high-stakes environment of molten metal processing, temperature control is paramount to quality, efficiency, and safety. The disposable thermocouple is the critical tool for capturing this data point accurately and swiftly. However, with multiple types available—primarily S, B, and R—a common question arises: Which one is the optimal choice for my specific application?

Selecting the wrong type can lead to inaccurate readings, accelerated wear, and significantly higher operating costs. This guide will demystify the differences between S, B, and R type thermocouples and provide a clear framework to make an informed, cost-effective decision for your operation.

Core Differences: A Matter of Precious Metal Alloy

S, B, and R types are all Noble Metal thermocouples, renowned for their superior stability and accuracy at high temperatures. Their key difference lies in the platinum-rhodium alloy composition of their wires, which dictates their performance characteristics.

| Feature | S Type (Platinum Rhodium – 10% / Platinum) | R Type (Platinum Rhodium – 13% / Platinum) | B Type (Platinum Rhodium – 30% / Platinum Rhodium – 6%) |

|---|---|---|---|

| Construction | GP: Rhodium 10%/Platinum GN: Pure Platinum |

GP: Rhodium 13%/Platinum GN: Pure Platinum |

GP: Rhodium 30%/Platinum GN: Rhodium 6%/Platinum |

| Standard Range | 0~1450°C (32~2642°F) | 0~1450°C (32~2642°F) | 600~1700°C (1112~3092°F) |

| Short-term Max | 1600°C (2912°F) | 1600°C (2912°F) | 1800°C (3272°F) |

| Stability | Excellent | Very Good | Superior (Best in Class) |

| Mechanical Strength | Standard | Good | Highest |

| Oxidation Resistance | Good | Very Good | Excellent |

| Cost | High | Highest | Medium (Best Value at High T) |

The Simple Analogy:

-

S Type is the versatile “industry standard.”

-

R Type is the “high-precision” variant of S, with marginally better performance at a premium cost.

-

B Type is the “heavy-duty champion” for extreme temperatures, outperforming the others significantly above 1600°C.

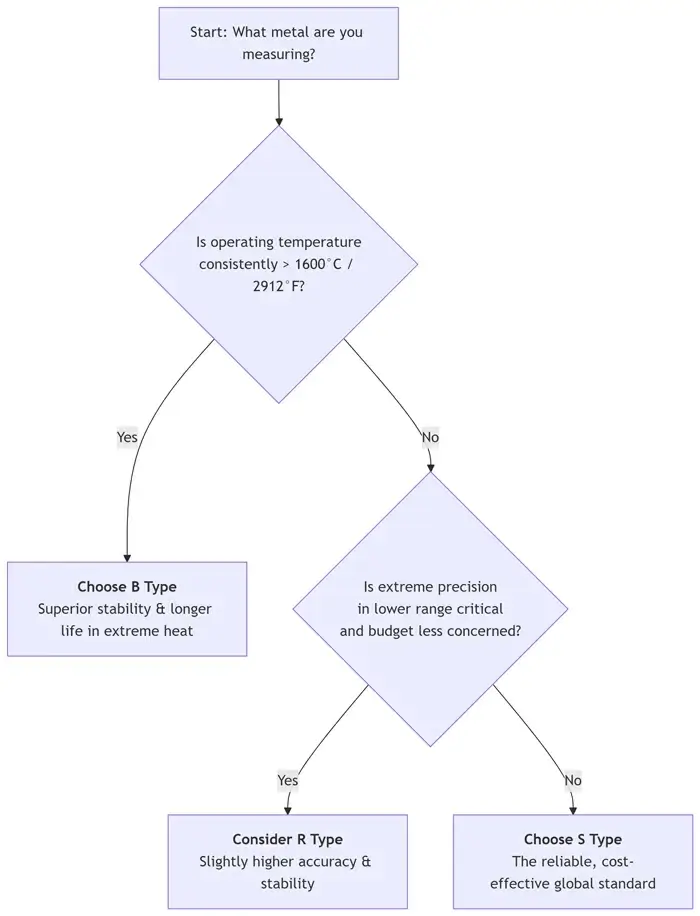

How to Choose: A Practical Decision Framework

Decision Workflow:

Start: What metal are you measuring?

Is operating temperature

consistently > 1600°C / 2912°F?

Choose B Type

Superior stability & longer life in extreme heat

Is extreme precision

in lower range critical

and budget less concerned?

Consider R Type

Slightly higher accuracy & stability

Choose S Type

The reliable, cost-effective global standard

Temperature: The Primary Determining Factor

-

For processes consistently operating BELOW 1600°C (2912°F):

This includes carbon steel, iron processing, and non-ferrous metal melting (e.g., copper, aluminum).

→ The S Type is almost always sufficient and the most economical choice. It is the established standard for most foundries and mills worldwide. -

For processes AT or ABOVE 1600°C (2912°F):

This includes stainless steel, specialty alloy refining, LF furnace operations, and superalloy production.

→ The B Type is unequivocally recommended. Its alloy construction offers far greater stability and resistance to grain growth at these temperatures. This translates to longer life and consistent accuracy. Using an S-type in this range leads to rapid deterioration and inaccurate readings, increasing your cost-per-accurate-reading.

Budget: Balancing Performance and Total Cost of Ownership (TCO)

-

S Type: Offers the best value for money for the majority of applications.

-

R Type: Commands the highest price per unit. Its marginal gains over S-type are often only justified in laboratory settings or for specific calibration purposes.

-

B Type: While the unit cost is higher than S-type, its dramatically extended lifespan in high-temperature applications results in a lower cost-per-successful-measurement, providing better long-term value.

Process Conditions and Requirements

-

Oxidation Resistance & Lifespan: B Type > R Type > S Type. In aggressive atmospheres or where longer immersion times are required, B Type provides more robust performance.

-

Mechanical Strength: The thicker alloy wires of the B Type offer greater resistance to the corrosive and abrasive nature of molten slag and metal.

Conclusion and Final Recommendations

| Your Operational Scenario | Recommended Type | Reasoning |

|---|---|---|

| Carbon Steel, Cast Iron, Non-Ferrous (< 1600°C) | S Type | The reliable, cost-effective global standard for these applications. |

| High-Accuracy R&D or Low-Temp Calibration | R Type | Offers slightly higher stability and EMF output for precision-critical tasks. |

| Stainless Steel, Specialty Alloys, High-Alloy Steels (≥ 1600°C) | B Type | Unmatched stability and longevity in extreme heat, ensuring data integrity. |

| Uncertain Conditions or Highly Variable Processes | B Type | Provides the safest performance buffer and greatest operational flexibility. |

Pro Tip: When in doubt, consult SF-Foundry technical support representative. Provide SF-Foundry with your specific process details (e.g., grade of metal, target temperature, measurement location, current challenges). They can offer data-driven advice to ensure you select the most efficient and economical solution for your needs.

Choosing correctly is not just about a single measurement—it’s about ensuring consistent product quality, optimizing operational efficiency, and managing your bottom line.