Non-metallic inclusions (such as oxides, slag, refractory particles, etc.) in molten metal are key factors affecting the quality of castings. Zirconia (ZrO₂) foam ceramic filters have become an efficient solution for filtration of molten metals such as aluminum, copper, cast iron, and stainless steel due to their excellent high-temperature stability, chemical inertness, and controllable pore structure. This paper discusses in detail the preparation process, filtration mechanism, key performance parameters, and application of zirconia foam ceramics in metal casting, and compares the advantages and disadvantages of different filtration technologies. Finally, the future development trend is prospected.

Keywords: zirconia; foam ceramics; metal filtration; casting; inclusions

Introduction

During the metal casting process, non-metallic inclusions in the molten metal can cause defects such as pores and cracks in the castings, which seriously affect their mechanical properties and service life. Traditional metal filtration methods (such as fiberglass mesh filters and honeycomb ceramic filters) are difficult to meet the requirements of high temperature and high cleanliness. Zirconia foam ceramics have become a key filtration material for high-end casting (such as aircraft engine blades and automobile alloy wheels) due to their high melting point (~2700°C), low thermal conductivity and excellent thermal shock stability.

Preparation and characteristics of zirconia foam ceramics

Preparation process

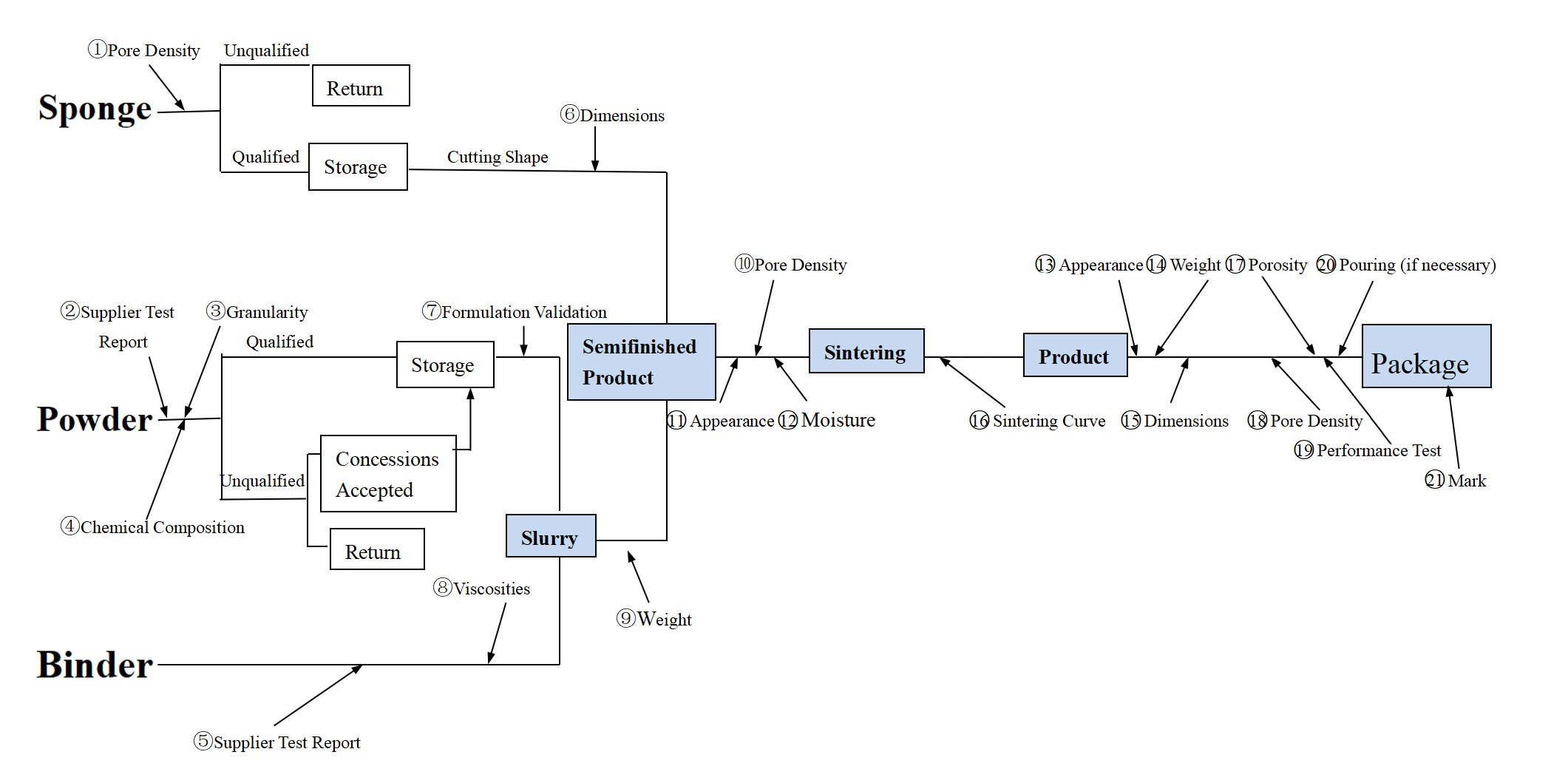

Zirconium oxide foam ceramics are mainly prepared by organic foam impregnation method, and the process is as follows:

- Slurry preparation: Stabilized zirconia is mixed with a binder and a dispersant to form a uniform slurry.

- Impregnation molding: The polyurethane foam template is immersed in the slurry, and the excess slurry is squeezed out to form a uniform coating.

- Drying and sintering: First remove organic matter at low temperature (200-400°C), and then sinter at 1500-1800°C to form a three-dimensional mesh porous structure.

Key performance parameters

- Pore size (PPI): usually 10-30 PPI (pores/inch).

- Porosity: 75%-90%, affecting filtration efficiency and melt flow rate.

- Compressive strength: ≥5 MPa, ensuring the ability to withstand the impact of metal melt.

Metal melt filtration mechanism

Zirconium oxide foam ceramics achieve efficient impurity removal through deep filtration, and the mechanisms include:

- Mechanical interception: large particles (>50 μm) are physically blocked.

- Adsorption effect: tiny particles (<10 μm) adhere to the pore wall due to surface force.

- Turbulent sedimentation: the melt flow rate is reduced, causing impurities to settle at the front end of the filter.

Case: After a certain aerospace casting used 20 PPI zirconia filters, the inclusions were reduced by 70% and the fatigue life was increased by 30%.

Comparison with other filtration technologies

| Technology | Advantages | Limitations |

|---|---|---|

| Fiberglass Mesh Filter | Low cost, easy installation | |

| Honeycomb Ceramic Filter | High flux | Poor filtration effect on tiny impurities |

Zirconium oxide foam ceramic has the best comprehensive performance, especially suitable for high temperature and high precision casting.

Conclusion

Zirconium oxide foam ceramic filters show irreplaceable advantages in metal melt filtration, especially in the fields of high-temperature alloys and precision casting. In the future, through material modification and process optimization, its filtration efficiency and economy will be further improved, promoting the development of high-end manufacturing industry.