Aluminum alloy casting is a metal forming process widely used in modern industry, especially in the fields of automobile, aerospace, electronics and mechanical manufacturing. However, aluminum liquid is very easy to absorb hydrogen and mix with impurities such as oxides and slag during smelting and pouring. These defects will directly affect the mechanical properties, air tightness and surface quality of the casting. In order to ensure the purity of aluminum liquid, degassing rotors have become a common degassing tool in aluminum alloy casting.

The importance of degassing rotors in aluminum alloy casting

What is the reason for using degassing rotors in alloy casting?

During the aluminum alloy smelting process, aluminum liquid will react with water vapor, oil stains, furnace lining materials, etc. in the air, resulting in the dissolution of hydrogen. In addition, the addition of alloying elements (such as magnesium, silicon, etc.) and the residual paint, grease, etc. in the process of waste aluminum recycling will increase the hydrogen content and inclusion content of aluminum liquid.

When the aluminum liquid cools and solidifies, the dissolved hydrogen will precipitate and form tiny pores (pinhole defects), while oxides and slag will become crack sources, reducing the strength, toughness and corrosion resistance of the casting. Therefore, dehydrogenation and impurity removal are essential processes before aluminum alloy casting.

What is the function of the degassing rotor in aluminum alloy casting?

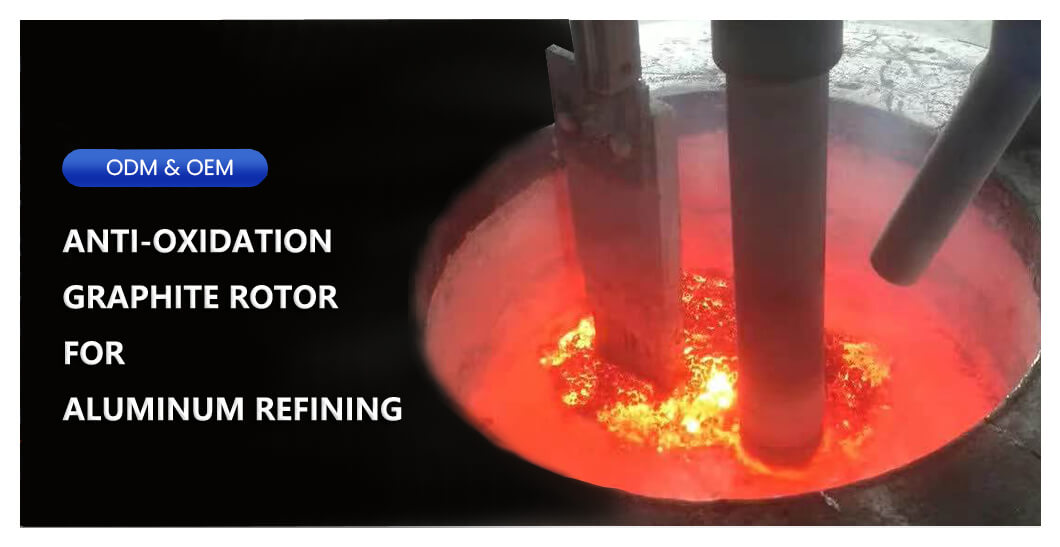

The degassing rotor produces a large number of tiny bubbles in the aluminum liquid by rotating and spraying inert gas (such as argon or nitrogen). During the rising process, these bubbles use the principle of partial pressure difference to adsorb the hydrogen dissolved in the aluminum liquid and bring it out of the liquid surface, while adhering to the suspended oxides and inclusions, thereby purifying the aluminum liquid.

Compared with traditional flux degassing or static degassing, the advantages of the degassing rotor are:

- High dehydrogenation efficiency: It can quickly reduce the hydrogen content in the aluminum liquid to below 0.1 mL/100g Al, greatly reducing pore defects.

- Removing inclusions: Microbubbles can effectively capture non-metallic impurities such as alumina and slag, and improve the purity of molten aluminum.

- Strong adaptability: Applicable to a variety of aluminum alloys (such as A356, ADC12, ZL101, etc.) and different casting processes.

What casting processes are degassing rotors used for?

Applicable processes

Degassing rotors are widely used in casting processes that require high purity of molten aluminum, mainly including:

Continuous casting (DC Casting)

Continuous casting is mainly used to produce aluminum plates, bars and profiles, such as high-strength aluminum alloys for aerospace. Since the aluminum liquid needs to remain in a flowing state for a long time, the degassing rotor is usually installed between the holding furnace and the casting machine for online continuous degassing to ensure that there are no pores and inclusion defects inside the aluminum ingot.

Low Pressure Casting

Low pressure casting is often used to produce high-quality castings such as automobile wheels and engine blocks. The degassing rotor is used for degassing before the aluminum liquid is transferred to the low-pressure casting machine to avoid internal looseness or surface defects of the casting caused by hydrogen precipitation.

Gravity casting (metal mold/sand casting)

In gravity casting, the aluminum liquid relies on its own weight to fill the mold cavity, the cooling speed is slow, and it is more likely to form pores. The application of the degassing rotor can significantly improve the density of thick and large castings (such as gearbox housings).

Semi-solid casting (SSM)

Semi-solid casting requires aluminum liquid to be formed in the solid-liquid phase interval. The degassing rotor can be used for simultaneous degassing during the slurry preparation stage to avoid the gas contained in the slurry affecting the quality of the final casting.

Key processing links

The timing of the use of the degassing rotor directly affects the degassing effect, mainly involving the following key links:

- Degassing after smelting: After the aluminum liquid reaches the target temperature and adjusts the composition, dehydrogenation and impurity removal are immediately carried out.

- Purification after alloying: After adding easily oxidized elements such as magnesium and silicon, degassing is required again to avoid the increase of inclusions.

- Final treatment before pouring: After the aluminum liquid is transferred to the ladle or holding furnace, the last degassing is carried out to ensure that the aluminum liquid is pure during pouring.

Why choose graphite degassing rotor?

In aluminum alloy casting, there are various degassing methods, such as flux degassing, vacuum degassing, rotary jet degassing, etc., but graphite degassing rotor has become the mainstream choice in the industry due to its unique performance. The main advantages include:

- Excellent high temperature resistance: Graphite materials can withstand high temperature aluminum liquid erosion above 700℃ for a long time without softening or deformation, ensuring long-term stable operation.

- Strong chemical stability: Graphite does not react with aluminum liquid or inert gas, avoids the introduction of new impurities, and ensures the stability of the chemical composition of aluminum liquid.

- Self-lubricating properties: The natural lubricity of graphite reduces the friction loss during rotor rotation, prolongs service life, and reduces maintenance costs.

- Efficient degassing capability: Compared with static degassing or flux degassing, graphite rotors generate micron-sized bubbles through high-speed rotation (300-800 rpm), and the dehydrogenation efficiency is increased by more than 50%.

- Economy and applicability: Compared with titanium alloy rotors or vacuum degassing equipment, graphite rotors are lower in cost and suitable for small and medium-sized foundries, while meeting the quality requirements of high-end castings.

SF-Foundry: Professional aluminum alloy casting material supplier

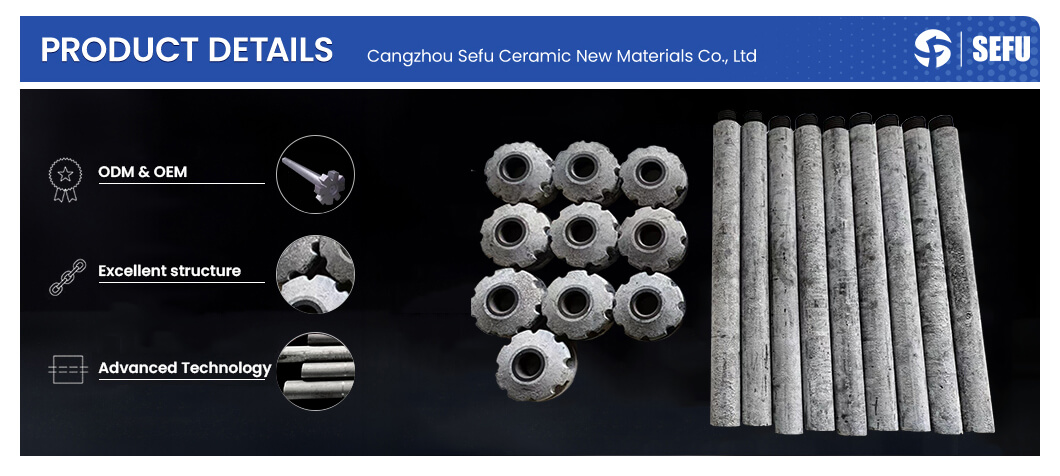

As a company focusing on the research and development and production of casting materials, SF-Foundry is committed to providing high-performance purification solutions for the aluminum alloy casting industry. Our products include:

- Graphite Degassing Rotor: using high-purity graphite, through anti-oxidation treatment, strong corrosion resistance and long service life.

- Ceramic Foam Filters: effectively intercepting tiny inclusions in aluminum liquid, reducing secondary oxidation and turbulent entrainment, and further improving the quality of aluminum liquid.

- Auto Pour Ladles: Customizable tools for transferring and pouring molten aluminum, with special coating treatment for longer service life.

- Vacuum Formed Ceramic Fiber Tap Out Cone: Effectively controls the flow of molten aluminum, excellent sealing effect.

We are well aware of the strict requirements of aluminum alloy casting on material purity, so all products of SF-Foundry undergo strict quality inspection to ensure that customers are provided with stable and reliable casting auxiliary materials. Whether it is continuous casting, low-pressure casting or precision casting production, we can provide customized solutions to help companies improve the casting qualification rate and market competitiveness.

Conclusion

The graphite degassing rotor greatly improves the mechanical properties and surface quality of castings in aluminum alloy casting through efficient hydrogen and impurity removal capabilities. With the growing demand for lightweight automobiles and high-end aerospace parts, the requirements for the purity of molten aluminum will become higher and higher, and graphite degassing technology will continue to play a key role.

As a professional casting material supplier, SF-Foundry will continue to optimize graphite degassing rotors and related products to provide more efficient and economical purification solutions for global aluminum alloy casting companies. If you need more technical details or product information, please contact us to discuss the optimal solution for aluminum alloy casting.