Sustainability is no longer a secondary objective in the foundry industry—it is a strategic priority. Rising raw material costs, stricter environmental regulations, and customer demand for greener manufacturing are pushing foundries to rethink every component of their production systems. One area gaining increasing attention is the gating system—specifically, the adoption of paper casting runners in iron casting applications.

Paper casting runners offer a practical and scalable solution for foundries seeking to reduce waste, lower costs, and improve environmental performance—without compromising casting quality. In iron casting processes such as lost foam casting and traditional sand casting, they are proving to be a forward-looking alternative to conventional runner systems.

The Sustainability Challenge in Modern Foundries

Foundries are energy-intensive operations. From melting metal to mold preparation and finishing, every stage consumes resources and generates emissions. Traditional gating systems—often made of metal—contribute to:

-

Increased metal consumption

-

Higher remelting and recycling loads

-

Additional energy use

-

Greater material waste

As environmental standards tighten and ESG reporting becomes more common, foundries are under pressure to reduce their carbon footprint while maintaining productivity and quality.

This is where paper casting runners present a compelling opportunity.

What Makes Paper Casting Runners Different?

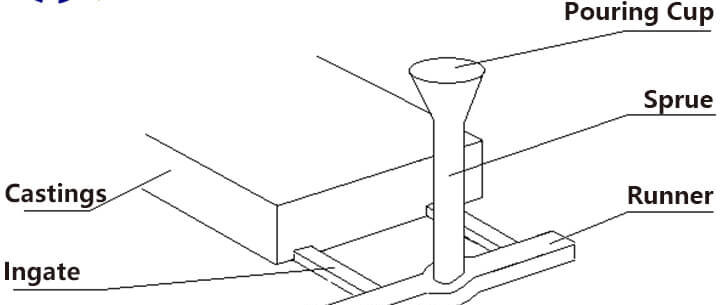

A paper casting runner is a pre-formed gating component made from engineered, heat-resistant paper materials. It is designed to guide molten iron into the mold cavity during pouring, functioning similarly to conventional runner systems—but with significantly reduced material mass and environmental impact.

Importantly:

-

Paper casting runners are suitable for iron casting processes, including gray iron and ductile iron.

-

They are widely used in lost foam casting (EPC) and traditional sand casting systems.

-

They are not suitable for aluminum casting, due to material compatibility and performance limitations.

Their role in sustainable foundry operations lies in both material efficiency and process optimization.

Reduced Metal Consumption and Remelting

Traditional metal runner systems solidify along with the casting and must be removed and remelted. While recycling is standard practice, remelting:

-

Consumes energy

-

Increases furnace load

-

Extends production cycles

-

Adds operational costs

Paper casting runners significantly reduce the total metal mass required in the gating system. With less excess metal to handle, foundries benefit from:

-

Lower melt volume requirements

-

Reduced furnace energy consumption

-

Shorter melting cycles

-

Improved yield ratios

Higher casting yield directly translates into improved sustainability performance.

Lower Carbon Footprint in Iron Casting Operations

Sustainability metrics in iron foundries are increasingly tied to energy intensity per ton of output. Since paper runners reduce remelt mass and gating metal volume, they indirectly:

-

Decrease total energy consumption

-

Reduce CO₂ emissions per casting

-

Improve material efficiency

In large-scale gray iron and ductile iron operations, even small yield improvements can create measurable environmental impact across annual production volumes.

For foundries seeking ISO 14001 compliance or ESG benchmarking improvements, gating system optimization is a practical and measurable step forward.

Material Efficiency in Lost Foam Casting (EPC)

In lost foam casting, patterns are vaporized as molten iron fills the mold. Integrating paper casting runners into this system offers several sustainability advantages:

-

Lightweight components reduce handling energy

-

Compatible burnout behavior supports clean mold filling

-

Simplified gating reduces excess metal

Because lost foam casting already eliminates the need for cores in many designs, combining it with paper runners further enhances process efficiency.

The result is a streamlined iron casting workflow with reduced waste and improved environmental performance.

Improved Yield in Traditional Sand Casting

In traditional sand casting operations, runner design directly impacts:

-

Mold filling stability

-

Turbulence control

-

Defect rates

-

Cleaning and finishing workload

Paper casting runners allow foundries to design optimized gating geometries while reducing the amount of solidified runner metal attached to castings.

This contributes to:

-

Less grinding and fettling

-

Lower labor intensity

-

Reduced post-processing energy

-

Shorter production cycles

From a sustainability standpoint, reducing secondary processing is just as important as optimizing melting efficiency.

Reduced Handling and Workplace Impact

Sustainability also includes worker safety and ergonomics.

Paper casting runners are:

-

Lightweight

-

Easy to transport and install

-

Simpler to store and manage

Compared to heavy metal runner systems, they reduce manual handling strain and improve operational efficiency on the foundry floor.

Better ergonomics contribute to long-term operational sustainability—not just environmental performance.

Alignment with Green Manufacturing Trends

Global manufacturing trends increasingly emphasize:

-

Resource efficiency

-

Waste reduction

-

Cleaner production technologies

-

Circular economy models

Paper casting runners align naturally with these principles. By minimizing unnecessary metal mass and optimizing gating performance, they help foundries transition toward leaner, more responsible production systems.

As regulatory frameworks continue evolving worldwide, proactive adoption of sustainable gating solutions positions foundries ahead of compliance pressures.

Design Considerations for Sustainable Performance

To fully realize the sustainability benefits of paper casting runners in iron casting, proper engineering design is essential. Key considerations include:

Flow Optimization

Runner dimensions must ensure stable molten iron flow without excessive metal volume.

Thermal Performance

Materials must withstand iron pouring temperatures in gray and ductile iron applications.

Mold Integration

The gating system must integrate seamlessly into lost foam or sand mold configurations.

Structural Integrity

Despite being lightweight, the runner must maintain strength during pouring.

When properly designed, paper casting runners provide both mechanical reliability and environmental efficiency.

Addressing Limitations Clearly

While paper casting runners offer strong sustainability benefits in iron casting, clarity about their application range is essential:

-

They are ideal for iron casting processes, including lost foam and sand casting.

-

They are not intended for aluminum casting.

-

They must be engineered specifically for high-temperature iron applications.

Understanding these boundaries ensures optimal performance and avoids misuse.

The Future of Sustainable Foundry Practices

The future of foundry operations will be defined by efficiency, environmental accountability, and smart process optimization. Sustainability improvements will not come solely from new furnaces or emission controls—but from incremental innovations across the entire production chain.

Paper casting runners represent one such innovation.

By improving yield, reducing remelt requirements, lowering energy consumption, and streamlining iron casting operations, they offer a practical pathway toward greener foundry practices.

For iron foundries committed to long-term competitiveness and environmental responsibility, rethinking the gating system is no longer optional—it is strategic.

Paper casting runners are not just a product innovation. They are a process optimization tool that aligns operational efficiency with sustainable manufacturing goals.

And that is why they represent the future of sustainable foundry practices.