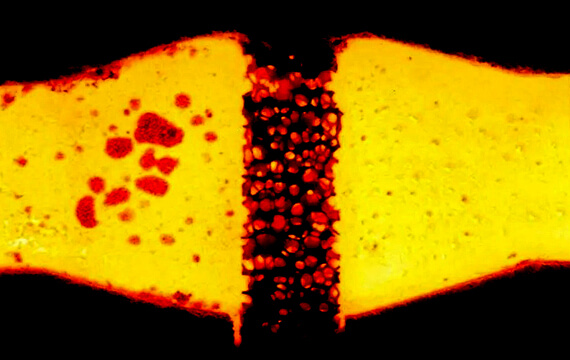

Silicon carbide ceramic foam filter (Sic Foam Filter) is a high-performance material for filtration of metal melts (such as molten iron), which is widely used in the foundry industry to improve the quality of castings. It removes impurities in the melt, such as oxides and non-metallic inclusions, by physical interception and chemical adsorption.

Application of silicon carbide ceramic foam filter in molten iron filtration and high temperature resistance

- High melting point: The melting point of silicon carbide is about 2700°C, which is much higher than the pouring temperature of molten iron (usually between 1300°C and 1500°C), so it can work stably.

- Excellent thermal shock stability: It can withstand the rapid temperature changes during molten iron pouring to avoid cracking.

- High efficiency filtration: High porosity and uniform pore structure can effectively remove impurities in molten iron, such as oxides and non-metallic inclusions, and improve the quality of castings.

- Chemical stability: It does not react chemically with molten iron at high temperatures to ensure the filtration effect and purity of molten iron.

High temperature resistance

Silicon carbide ceramic foam filter has excellent high temperature resistance and can work at 1560°C and higher temperatures for a long time. The specific performance is as follows:

- High temperature stability: It can still maintain structural stability at 1560°C without softening or deformation.

- Oxidation resistance: It has good oxidation resistance at high temperatures and prolongs service life.

- Mechanical strength: It still maintains high strength at high temperatures and can withstand the impact and pressure of molten iron.

Application advantages

- Improve casting quality: Effectively remove impurities in molten iron and reduce casting defects.

- Extend mold life: Reduce the erosion of impurities on the mold and extend the use time of the mold.

- Economic benefits: Reduce scrap rate and reduce production costs.

Summary

Silicon carbide ceramic foam filter is very suitable for molten iron filtration. It has excellent high temperature resistance and can work stably at 1560°C and higher temperatures, significantly improving molten iron quality and casting efficiency.