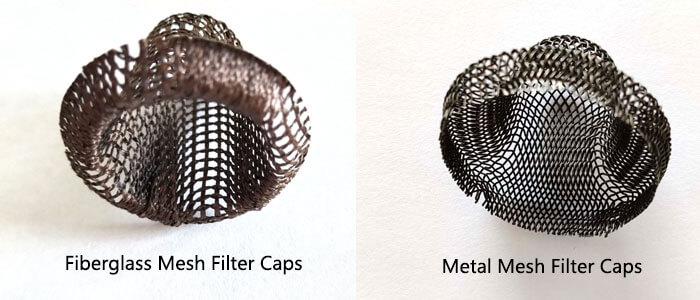

In the foundry industry, different types of filters are used to improve the casting quality. Fiberglass mesh filters and metal mesh filter caps are the most commonly used filters. Both of these filters have their advantages and disadvantages, but in a positive light, they both have strong features that make them suitable for certain foundry applications.

Advantages of Fiberglass Mesh Filter Caps

One of the major advantages of fiberglass mesh filter caps is their ability to capture small impurities in the metal. This filter cap is made of highly efficient fibers that effectively trap any small impurity that can cause defects in the casting. Fiberglass mesh filter caps have a high filtering capacity due to the high surface-to-volume ratio of the fibers. This makes it possible for the filters to remove more impurities from the melt without having to change the filters often. Another positive feature is that fiberglass mesh filter caps are less expensive than metal mesh filters. The cost-effectiveness makes them more popular in foundry applications where the cost is an issue.

Benefits of Metal Mesh Filter Caps

On the other hand, metal mesh filter caps offer more benefits in terms of durability and versatility. The metal mesh filters are made of strong materials that can withstand high temperatures from the melted metal. The metal mesh filter caps can be made of different metals, depending on the application. They can be made from stainless steel, nickel, or copper, which all have different melting points, and can be used for different types of alloys. Metal mesh filters provide a consistent flow rate that can reduce turbulence and improve the flow of metal during the casting process.

Fiberglass Mesh Filter Cap and Metal Mesh Cap in Foundry

Both fiberglass mesh filter caps and metal mesh filter caps have their applications in the foundry industry. The decision on which filter to use will depend on the specific needs of the foundry. Fiberglass mesh filter caps are ideal for foundries that deal with smaller casting and require frequent replacement of filters. Metal mesh filter caps, on the other hand, are more suitable for foundries that deal with large casting and require long-lasting filters that can withstand high temperatures.

In conclusion, both fiberglass mesh filter caps and metal mesh filter caps have their positive attributes, making them essential in the foundry industry. Fiberglass mesh filter caps are more cost-effective and have a higher filtering capacity, while metal mesh filter caps are more versatile and durable. Choosing the right filter cap will depend on the specific needs of the foundry and the casting processes involved. Regardless of the choice, either option will play a significant role in ensuring high-quality castings that can meet the desired standards.