The filter is an important part of the casting process. It is used to remove impurities, particles, and other components from the molten metal before casting. The type of filter used in the casting process depends on the type of alloy being cast and the desired end product.

Filter media is a group of materials that can be used in the casting process to improve the quality of the end product. Casting filters are specially designed to prevent the escape or release of unwanted particles and debris that can be present in molten metal. These particles can cause a variety of casting problems such as porosity and inclusions, which can affect the strength and integrity of the end product.

In addition, filter media can also be used to control the composition of the alloy being cast. Different filter media can be combined to ensure the alloy meets specific chemical and metallurgical specifications. For example, a combination of filter media can reduce phosphorus levels in steel to improve weldability and formability.

The use of filter media in the casting process helps to improve the quality and performance of the end product. It also helps to reduce production costs by eliminating rework and scrap, as well as improving the efficiency and turnaround time of the casting process.

The Different Materials Filters in Casting

In the field of casting, various types of filter medias are used to enhance the quality of casted components by removing impurities from the molten metal. Modern foundries generally use the following filter media:

Fiberglass Filter Mesh for Casting:

Used for filtration in the casting process to remove impurities from molten metal.

Honeycomb Ceramic Filter for Casting:

Ideal for filtering molten metal in casting applications, providing effective filtration due to its honeycomb structure.

Silicon Carbide Bonded Particle Filter for Ultra-Precise Aluminum Filtration:

Material: Silicon Carbide

Application: Specifically designed for filtering ultra-precise aluminum melts in casting processes.

Ceramic Foam Filter for Casting:

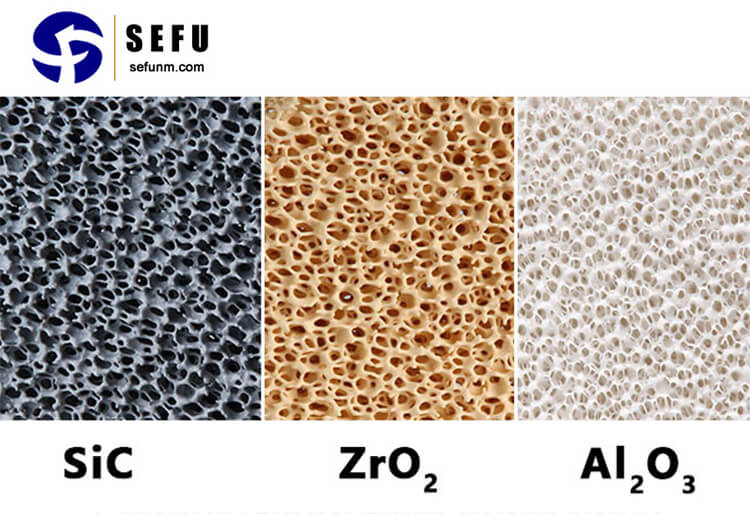

Silicon Carbide Foam Ceramic Filter:

- Material: Silicon Carbide

- Temperature Resistance: Up to 1560°C

- Application: Suitable for filtering molten metal in casting processes, especially for casting iron and copper components

Automotive Cast Iron Components: Used in the production of automotive cast iron parts such as engine blocks, cylinder heads, and brake components.

- Material: Alumina

- Temperature Resistance: Up to 1200°C

- Application: Ideal for filtering molten aluminum in casting processes, commonly used for:

Automotive Aluminum Components: Essential for casting automotive aluminum parts like cylinder heads, wheels, and transmission components.

- Material: Zirconia

- Temperature Resistance: Up to 1700°C

- Application: Suitable for high-precision casting, including:

Aerospace Components: Used in the casting of high-performance aerospace parts such as turbine blades, engine components, and structural elements.

- Material: Magnesia

- Temperature Resistance: Up to 1200°C

- Application: Employed for filtering magnesium and magnesium alloy melts in precision casting, including components like:

Aerospace Magnesium Alloy Parts: Utilized in the casting of lightweight and high-strength magnesium alloy components for aerospace applications, including structural elements and engine parts.

These filters play a crucial role in improving the quality of casted components by effectively removing impurities and ensuring a clean and smooth casting process. The different materials filters in casting are tailored for specific casting needs, ensuring the production of high-quality automotive, aerospace, and precision components in the casting industry.

If you need to know more about filters in casting, or need to purchase, please click on the right side of ‘Reach me Now!’ to leave your contact information and needs. We have decades of experience in researching and producing casting filters, and our experienced experts will contact you.

You can also contact us directly through the following contact information:

- Email: info@sf-foundry.com

- WhatsApp: +8613785803358