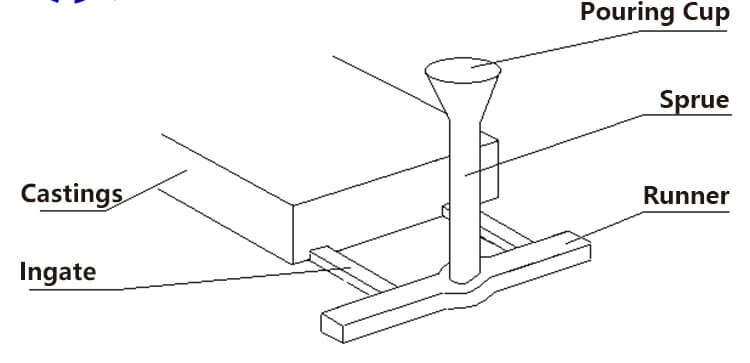

In sand casting, the gating system plays a critical role in ensuring high-quality castings by controlling the flow of molten metal into the mold. Among its key components, the runner is essential for efficient metal distribution, minimizing defects, and improving casting integrity.

The Role of the Runner in Sand Casting

The runner is a horizontal channel that connects the sprue (the vertical passage from the pouring basin) to the ingates (the entry points into the mold cavity).

Its primary functions include:

Controlled Metal Flow

The runner ensures molten metal flows smoothly into the mold, reducing turbulence that can cause gas entrapment, oxide formation, or cold shuts.

A properly sized runner maintains optimal speed—too fast can erode the mold, while too slow may lead to premature solidification.

Even Distribution to Multiple Cavities

In molds with multiple cavities, the runner branches out to feed each section uniformly, preventing uneven filling and inconsistent solidification.

Slag and Impurity Trapping

Well-designed runners incorporate slag traps (enlarged sections or filters) to capture oxides and impurities before they enter the casting.

Advanced systems may use ceramic foam filters (CFFs) or fiberglass mesh filters for cleaner metal flow.

Supporting Directional Solidification

The runner helps guide metal toward risers, ensuring proper directional solidification to minimize shrinkage defects.

Design Considerations for Effective Runners

- Shape: Typically trapezoidal or round to reduce heat loss and turbulence.

- Size: Must balance flow rate—too narrow causes excessive speed, while too wide slows filling.

- Placement: Should avoid sharp bends and abrupt changes in direction to maintain smooth flow.

Common Runner-Related Defects & Solutions

- Misruns (Incomplete Filling) → Increase runner size or improve gating design.

- Cold Shuts (Poor Metal Fusion) → Optimize runner layout to reduce turbulence.

- Slag Inclusions → Add slag traps or ceramic filters.

Conclusion

The runner is a fundamental element in sand casting, ensuring efficient, clean, and controlled metal delivery into the mold. Proper design reduces defects, improves yield, and enhances casting quality.

At SF-Foundry, we provide advanced gating solutions, including ceramic foam filters (CFFs) and optimized runner designs, to help foundries achieve superior casting performance. Contact us for expert technical support and high-performance refractory materials.