Introduction:

In the realm of foundry operations, the function of runner in casting stands as a cornerstone of metal shaping processes. Let’s delve into the multifaceted importance of runners from various perspectives to unravel their significance in the intricate world of foundry casting.

1. Precision in Metal Flow:

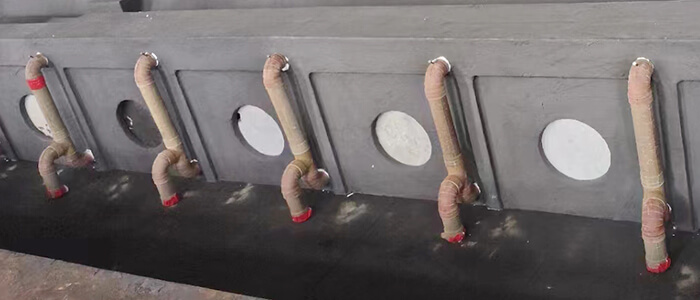

Runners in casting systems act as precision conduits, guiding the flow of molten metal with meticulous control from the furnace to the mold cavity. This regulated flow ensures that the metal fills the mold evenly and accurately, crucial for achieving intricate casting shapes with impeccable detail.

2. Efficiency and Productivity:

Efficiency is the hallmark of a well-designed runner system. By optimizing the layout and configuration of runners, foundries can enhance productivity by streamlining the metal pouring process, reducing wastage, and minimizing the time required for each casting cycle.

3. Quality Assurance:

Runners play a pivotal role in ensuring the quality of cast products. Through proper design and implementation, runners facilitate the elimination of defects such as shrinkage, misruns, and cold shuts, thereby upholding the standards of excellence in the final cast components.

4. Temperature Control and Solidification:

One of the critical functions of runners is to manage the temperature of the molten metal as it flows through the system. By controlling the cooling rate and solidification process, runners help prevent issues like hot tears and internal stresses, contributing to the overall integrity of the cast product.

5. Sustainability and Material Efficiency:

In the era of sustainable manufacturing practices, optimized runner systems play a vital role in reducing material wastage and energy consumption. By designing eco-friendly runners that minimize metal loss and enhance recycling capabilities, foundries can align their operations with environmental stewardship.

6. Advancements in Runner in Casting Technology:

The continuous evolution of runner technology has led to innovative designs that maximize efficiency and precision in casting operations. From computational fluid dynamics simulations to 3D printing of intricate runner structures, modern foundries are leveraging cutting-edge tools to push the boundaries of casting excellence.

Conclusion:

The function of runners in casting is not merely about channeling molten metal; it embodies a symphony of precision, efficiency, quality, and innovation in the foundry industry. By understanding and optimizing the role of runners in metal shaping processes, foundries can elevate their capabilities, reduce waste, and deliver superior cast products that meet the highest standards of craftsmanship.

For more insightful discussions on the complexities of foundry operations and the latest trends in metal shaping technologies, stay tuned for our upcoming blogs exploring the diverse facets of the casting process.