In the realm of foundry operations, the function of a mesh filter holds paramount importance in ensuring the quality and integrity of cast metal components. Mesh filters, particularly in the form of glass fiber filters, play a crucial role in the metal casting process by effectively removing impurities and enhancing the overall quality of the final product.

Understanding the Role of Mesh Filter in Foundry Applications

- Impurity Removal: Mesh filters act as a barrier against non-metallic inclusions present in molten metal. These impurities, if not effectively filtered out, can lead to defects such as porosity, slag inclusions, and sand inclusions in cast components.

- Enhanced Quality Control: By capturing contaminants and unwanted particles, mesh filters contribute to improving the cleanliness and purity of the molten metal, ultimately resulting in higher-quality castings with superior mechanical properties.

- Optimized Flow: Mesh filters are designed to regulate the flow of molten metal during the casting process, ensuring a smooth and consistent distribution of the material within the mold cavity. This controlled flow helps prevent turbulence and aids in achieving precise casting shapes and dimensions.

- Gas Removal: In addition to filtering out solid impurities, mesh filters also play a role in minimizing gas evolution during the casting process. By trapping gas bubbles and preventing their incorporation into the metal matrix, these filters contribute to reducing defects related to gas porosity in cast components.

The Advantages of Glass Fiber Mesh Filters in Foundry Operations

- High-Temperature Resistance: Glass fiber mesh filters are engineered to withstand the extreme temperatures encountered in metal casting processes, ensuring durability and longevity in demanding foundry environments.

- Chemical Stability: These filters exhibit excellent chemical stability, remaining unaffected by the corrosive nature of molten metals and metal alloys, thereby maintaining their filtering efficiency over extended periods of use.

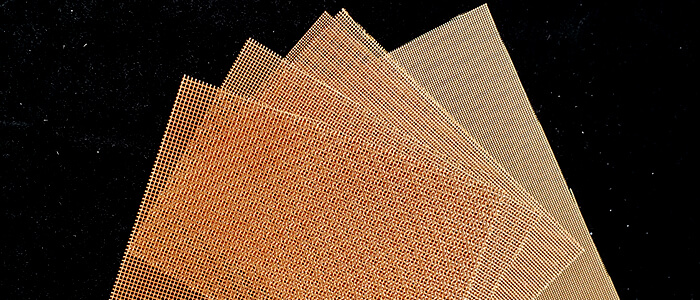

- Customization Options: Manufacturers like SEFU offer a range of glass fiber mesh filters in various shapes, sizes, and configurations, allowing foundries to select filters tailored to their specific casting requirements.

Conclusion

In conclusion, the function of a mesh filter in foundry applications is indispensable for achieving high-quality cast metal components free from defects and impurities. As a vital component in the casting process, glass fiber mesh filters not only enhance the quality of castings but also contribute to process efficiency and overall productivity in foundry operations.

For foundries seeking advanced filtration solutions that prioritize quality, performance, and reliability, glass fiber mesh filters from reputable manufacturers like SEFU offer a competitive edge in ensuring superior casting outcomes. Contact SEFU today to explore a comprehensive range of glass fiber mesh filters designed to elevate your foundry processes to new heights of excellence.