In the realm of casting processes, the formation of castings is inseparable from the gating system. The gating system comprises various components, including runners and gates. The design of the gating system plays a pivotal role in determining the quality of the final casting. When discussing gating systems, two key components often come into focus: runners and gates. These elements play distinct roles in the casting process, and below, we delve into the disparities between runners and gates.

Runners in Casting:

- Definition: Runners in casting are channel systems that transport molten metal from the gate to the mold cavity.

- Function: The primary role of a runner is to guide molten metal from the gate into the mold, ensuring uniform filling of the casting.

- Characteristics: Runners typically serve as the main channels within the gating system, and their design and layout impact the flow of metal and the quality of the casting.

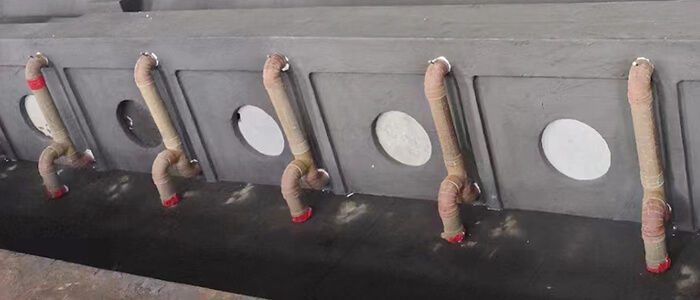

- Variety: Runners can take different forms, such as straight, curved, or branched, to accommodate various casting shapes and sizes.

Gates in Casting:

- Definition: A gate is the part of the gating system that connects to the mold cavity and allows molten metal to enter.

- Function: Acting as a control valve, the gate regulates the flow of metal, prevents gases or impurities from entering the mold cavity, and aids in forming the desired solidification structure.

- Characteristics: Gates typically sit at the end of the runner, directly connecting to the mold cavity, serving as the final gateway for metal flow.

- Variety: The design and shape of gates influence the speed, direction, and uniformity of metal injection, thereby impacting the quality of the cast part.

Distinctions between Runners and Gates in Casting:

- Diverse Functions: Runners guide molten metal to the mold cavity, while gates serve as the channels for metal entry into the mold.

- Varied Positions: Runners precede gates, playing a guiding role, whereas gates are positioned at the end of runners, directly connecting to the mold cavity.

- Differing Functions: Runners are primarily for filling the entire mold cavity, while gates control metal flow, preventing gas and impurities from entering.

In the casting process, the correct design and optimization of the gating system (including runners and gates) are critical for achieving high-quality castings. By comprehending the functions and disparities between runners and gates, casting engineers can better optimize the casting process to ensure the final products meet the desired quality and performance standards.

This blog aims to provide a clearer understanding of the roles and variances between runners and gates in casting. If you have any queries or require further insights into casting processes, feel free to reach out to us. Thank you for reading!