If you’re involved in metal casting, whether you’re a seasoned engineer or a newcomer, you’ve likely heard the terms “riser” and “feeder.” And you’ve probably noticed that people often use them interchangeably. This can be confusing. I remember when I was first learning about foundry processes, I spent a good amount of time trying to figure out if there was actually a difference.

So, let’s clear this up once and for all. In short: A riser is the object, and feeding is its primary function. But to truly understand casting defects and how to prevent them, we need to dive a bit deeper.

The Core Problem Both Are Designed to Solve

Before we distinguish between them, we must understand the common enemy in casting: solidification shrinkage.

Most metals and alloys contract as they change from a liquid to a solid. Imagine pouring a bucket of water into a complex ice cube tray. As it freezes, the ice expands. But with molten metal, the opposite happens—it shrinks. If there isn’t a continuous supply of liquid metal to fill the space left by this shrinkage, the result is shrinkage porosity or voids within your casting. These defects weaken the part and can lead to catastrophic failure.

This is where our two key players come in.

Riser: The “What” – The Reservoir Itself

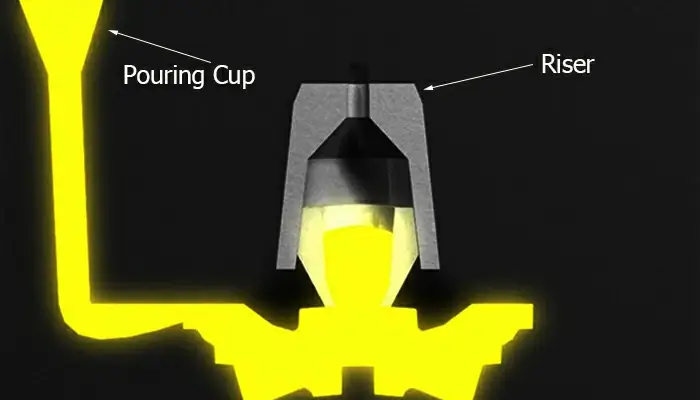

Think of the riser (also known as a feed head) as a strategic reservoir of molten metal. It’s that extra lump of metal you see on castings before it’s removed.

Key Characteristics of a Riser:

It’s a Physical Object: It has a shape, typically cylindrical, because this shape cools slowly.

Its #1 Job is to Solidify LAST: This is the most critical principle. Using Chvorinov’s Rule (which states that thicker sections take longer to freeze), risers are designed to be chunkiest part of the system. This ensures the metal inside stays liquid longer than the casting.

It’s Sacrificial: Once the casting has solidified, the riser is cut off and recycled. It is not part of the final product.

From my experience, a common question I get is: “What is a riser in casting?” Simply put, it’s your insurance policy against shrinkage cavities. Without a properly designed riser, you’re almost guaranteed to have a defective part.

Feeder: The “How” – The Function and The Channel

Now, here’s where the nuance lies. The term “feeder” is used in two closely related ways:

The Action (Feeding): This is the core function of the riser. Feeding is the active process of liquid metal flowing from the riser into the casting to compensate for shrinkage as it solidifies.

The Channel (The Feeder Neck): In more precise engineering talk, the “feeder” often refers to the passage or the “neck” that connects the riser reservoir to the casting. The design of this feeder neck is crucial—it must be narrow enough to allow for easy removal but wide enough to stay open and allow metal flow until the very end of solidification.

So, when we say a riser “feeds” the casting, we are describing its purpose. The riser does the feeding.

A Simple Analogy to Cement the Concept

Let’s use a simple analogy: Think of watering a plant.

-

The Watering Can is the Riser. It’s the reservoir that holds the extra water.

-

The Pouring of Water from the can into the soil is the Feeding action.

-

The Spout of the Can is the Feeder Neck, directing the flow to the right place.

The plant (the casting) needs water (molten metal) to grow and be healthy. You use the watering can (riser) to pour (feed) the water into the soil, ensuring the plant doesn’t dry out and shrink away from the pot. Once the plant is hydrated, you put the can away.

Answering Your Common Questions

Let’s quickly address some other related queries people often search for:

What is the purpose of a riser and a gate?

- Riser: Manages solidification shrinkage by supplying liquid metal.

- Gate: Channels molten metal from the pouring cup into the mold cavity. They work together but have completely different jobs. The gate fills the casting; the riser feeds it as it solidifies.

What are the different types of risers in casting?

- Top Risers: Sit on top of the casting, using gravity for efficient feeding.

- Side Risers: Attached to the side, used when the top isn’t accessible.

- Open Risers: Exposed to air (lose heat faster).

- Blind Risers: Buried in sand (lose heat slower, more efficient).

Conclusion

In summary, while the terms are intertwined, the distinction is helpful:

-

The Riser is the WHAT – the physical, sacrificial reservoir.

-

The Feeder is the HOW – the critical function it performs, often referencing the channel that enables it.

In everyday foundry language, calling the reservoir a “riser” is perfectly standard. But now you know that when someone talks about “feeding a casting,” they are referring to the vital process that the riser enables. Getting the riser design and feeding mechanism right is what separates a sound, high-integrity casting from a scrap one. So, next time you design a mold, remember: you’re not just adding a riser; you’re engineering a feeding system.