When you hear the word “ceramics,” what’s the first thing that comes to mind? For many, it’s a handmade vase or the coffee mug on your desk. I used to think the same way. But after years working in and around manufacturing, I’ve learned that the ceramic industry is one of the most vast and vital sectors in the world, silently building and powering our modern lives.

So, what exactly is it? In simple terms, the ceramic industry transforms inorganic, non-metallic materials (like clay and minerals) into indispensable products through the power of heat. But that simple definition hides an incredible story of innovation. Let’s break it down.

It’s Not Just Pottery: The Three Pillars of the Ceramic Industry

The industry is far from monolithic. We can understand it by looking at its three main branches.

Traditional Ceramics: The Foundation of Civilization

This is the ancient root of the industry. Think of the bricks in your home, the roof tiles overhead, or your bathroom sink and toilet (known as sanitaryware). These products are durable, cost-effective, and essential for construction and daily life. They are the workhorses of the industry, and their production is a testament to timeless manufacturing processes.

Advanced Ceramics: The High-Tech Engine

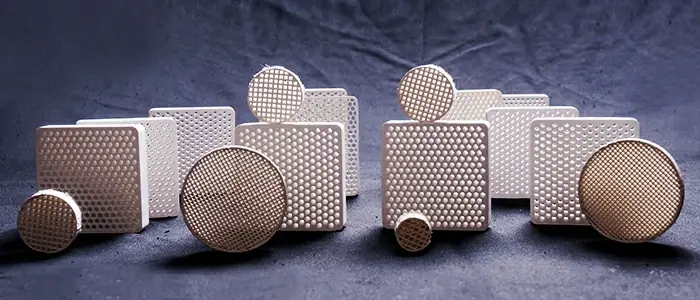

This is where things get fascinating. Advanced ceramics (or engineering ceramics) are the superheroes of the material world. Made from highly purified powders like alumina or silicon nitride, they are engineered for extreme performance.

- In your phone: Ceramic substrates are inside your smartphone, enabling it to function.

- In medicine: They are used for bioceramics like artificial joints and dental implants because they are compatible with the human body.

- In industry: They create components for aerospace, incredibly durable cutting tools, and parts for car engines that can withstand intense heat.

Whitewares: Where Art Meets Function

This category includes the products we interact with daily. Your dinner plates, the beautiful tiles on your kitchen wall, and that elegant porcelain figurine all fall under whitewares. They are characterized by their typically white, fired body and are almost always glazed to be non-porous, hygienic, and beautiful.

Why is the Ceramic Industry So Important?

From my perspective, the true value of this industry lies in its unique material properties. Ceramic products are typically:

-

Extremely hard and wear-resistant (think of the sandpaper you might use, which has ceramic abrasives).

-

Able to withstand high temperatures (the refractory bricks lining a steel furnace are a perfect example).

-

Excellent electrical insulators, which is critical for everything from power lines to your laptop.

-

Highly resistant to chemical corrosion, making them ideal for chemical plants and medical environments.

The main challenge? Their well-known brittleness. But this is precisely where advanced ceramic manufacturing is making huge strides, creating tougher, more reliable materials every year.

The Future is Ceramic: Key Trends to Watch

The industry isn’t resting on its laurels. As we look ahead, a few key trends are shaping its future:

-

Sustainability: The push for sustainable manufacturing is leading to more energy-efficient kilns and the use of recycled materials.

-

Additive Manufacturing: Yes, you can 3D print ceramics now! This allows for incredibly complex designs that were once impossible.

-

Material Science: The development of new composites and nanoceramics promises even greater strength and new functionalities.

Conclusion: An Industry Touching Every Aspect of Life

So, the next time you pick up a ceramic mug, remember that you’re holding a product from an industry that spans from the most ancient crafts to the frontiers of space exploration. The ceramic industry is not a relic of the past; it is a dynamic and critical force, essential for building our future.

Are you looking for specific information on ceramic materials or manufacturing processes? Feel free to explore our other articles on the topic!