Silicon Carbide (SiC) is a compound known for its exceptional properties that have led to its widespread applications across various industries. Let’s delve into the unique characteristics of SiC, its performance attributes, and touch upon its role in Silicon Carbide Ceramic Foam Filters.

Characteristics of Silicon Carbide (SiC):

- Hardness and Wear Resistance: SiC is renowned for its exceptional hardness and wear resistance, making it an ideal material for applications requiring durability and longevity.

- High Thermal Conductivity: SiC exhibits high thermal conductivity, allowing it to efficiently dissipate heat in electronic components and high-temperature environments.

- Wide Bandgap: The wide bandgap of SiC enables its use in high-power electronic devices, where it can operate at high voltages and temperatures.

- Chemical Inertness: SiC is chemically inert, making it resistant to corrosive environments and ideal for applications where chemical stability is crucial.

![]()

Applications of Silicon Carbide (SiC):

- Electronics and Semiconductor Industry: SiC is extensively used in power electronics, LEDs, and radio frequency devices due to its high thermal conductivity and wide bandgap properties.

- Abrasives and Cutting Tools: The hardness of SiC makes it a preferred material for manufacturing abrasive tools, grinding wheels, and cutting tools in industries requiring precision machining.

- Ceramics and Refractories: SiC ceramics are employed in high-temperature applications such as kiln furniture, crucibles, and refractory materials due to their excellent temperature resistance and thermal shock stability.

- Automotive and Aerospace: SiC is utilized in manufacturing components like brake discs and engine parts in the automotive and aerospace industries, benefiting from its lightweight nature and high thermal conductivity.

- Energy and Power Systems: SiC plays a crucial role in power electronics and energy storage applications, contributing to improved energy efficiency and power conversion in inverters, solar panels, and electric vehicles.

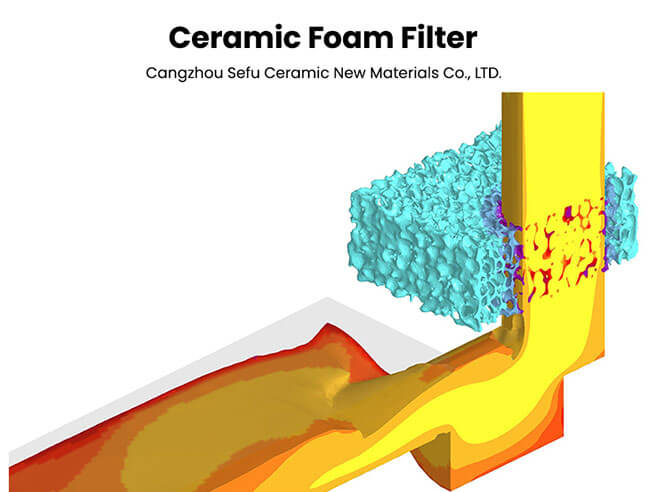

Role of Silicon Carbide Ceramic Foam Filters:

Silicon Carbide Ceramic Foam Filters are vital in the metallurgical industry for refining molten metals by removing impurities and non-metallic inclusions. These filters ensure clean metal casts and enhance the quality of end products in foundries and casting processes, contributing to improved product integrity and performance.

In conclusion, Silicon Carbide (SiC) stands as a versatile material with a wide range of applications across industries due to its unique properties and performance characteristics. Its significance in modern industrial processes, coupled with innovations like Silicon Carbide Ceramic Foam Filters, underscores its critical role in enhancing efficiency, performance, and quality across various sectors.