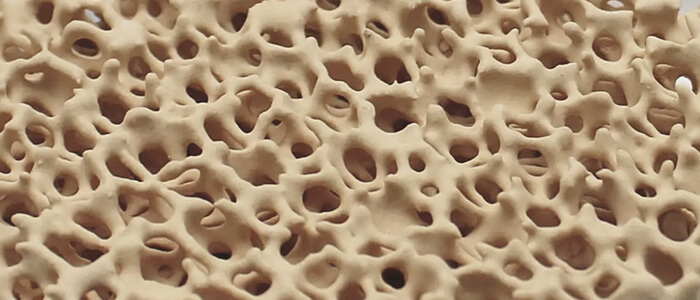

In the realm of modern metal casting, the utilization of magnesium oxide ceramic foam filters has revolutionized the quality and precision of cast metal components. These innovative filters, crafted from magnesium oxide, serve as indispensable tools in the intricate process of metal casting, ensuring the production of high-quality castings across various industries.

The Versatility of Magnesium Oxide Ceramic Foam Filters:

Magnesium oxide ceramic foam filters are specifically designed to effectively remove impurities, non-metallic inclusions, and oxides from molten metals during the casting process. Their high-temperature resistance and exceptional filtration properties make them ideal for enhancing the quality and integrity of cast components in applications ranging from aerospace to automotive industries.

Enhancing Casting Precision and Surface Finish:

One of the key roles of magnesium oxide ceramic foam filters is to enhance casting precision and surface finish. By precisely filtering out contaminants from molten metals, these filters contribute to producing smoother surfaces, finer details, and improved mechanical properties in the final cast products, ensuring superior quality and performance.

Applications Across Different Metal Alloys:

Magnesium oxide ceramic foam filters exhibit remarkable adaptability across various metal alloys, including magnesium, aluminum, steel, and copper. Their compatibility and efficiency in filtering out impurities make them essential components in metal casting processes, facilitating the production of defect-free castings with enhanced mechanical properties.

Optimizing High-Temperature Casting Processes:

With a maximum operating temperature of 1200°C, magnesium oxide filters excel in high-temperature casting processes. Their structural integrity and filtration efficacy under extreme temperatures ensure consistent and reliable performance, which is crucial for achieving high-quality castings in demanding applications that require elevated temperatures.

Conclusion:

In conclusion, the multifaceted applications of magnesium oxide ceramic foam filters in metal casting underscore their significance in enhancing casting precision, improving surface finish, and optimizing production processes across industries. By harnessing the capabilities of these advanced filters, manufacturers can achieve superior-quality castings with precision and efficiency, driving excellence in the art of metal casting.

For further information on how magnesium oxide filters can elevate your metal casting processes to new heights of quality and precision, do not hesitate to contact us. Let’s embark on a journey toward excellence and innovation in metal casting together.