Crafting High-Quality Castings: The Role and Importance of Gate and Runner in Foundry Processes

In the intricate art of metal casting, gates and runners often overlooked but crucial, play a defining role in ensuring the creation of flawless metal parts with precision and perfection.

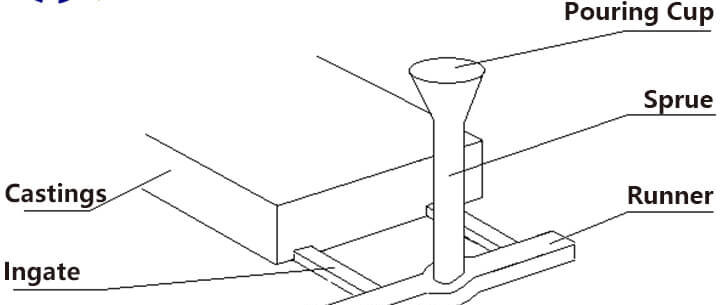

Understanding Gate and Runner in Metal Casting

1. The Significance of Gates

Gates serve as the vital conduits through which molten metal flows into the mold cavity during casting. A well-designed gate system facilitates uniform metal flow, mitigating the formation of defects like porosity and inclusions. Moreover, an appropriately engineered gate design minimizes metal oxidation and guarantees superior surface quality in the final castings.

2. The Functionality of Runners

Runners act as the network of channels linking the furnace to the gates. Their primary function is to guide molten metal to individual gates, ensuring complete mold cavity filling and preventing cold shuts and porosity. A well-crafted runner system ensures even metal distribution to all gates, leading to consistent casting quality.

The Criticality of Gate and Runner Design

- Control of Metal Flow: Gate and runner design directly influences the speed and direction of metal flow within the mold cavity, crucial for preventing turbulent metal flow and bubble formation.

- Defect Reduction: Properly designed gates and runners can reduce defects such as porosity, shrinkage cavities, and cold shuts, enhancing surface finish and integrity of castings.

- Enhanced Production Efficiency: Effective gate and runner design can boost production efficiency, reduce scrap rates, and lower manufacturing costs.

Conclusion

Gates and runners play a pivotal role in the metal casting process, profoundly impacting the quality and performance of the final castings. Through scientifically sound design and optimization, smooth metal flow, defect-free castings, improved production efficiency, and enhanced casting quality can be achieved. In the realm of metal casting, the importance of gates and runners cannot be overstated—they are key factors in the creation of superior castings.

For the best metal casting results, attention to detail in gate and runner design is paramount, ensuring a seamless production process and impeccable final products that meet the highest industry standards.

SEFU serves the foundry industry in various countries and provides high temperature resistant paper casting systems, including sprue tubes, pouring cups, elbows, T-tubes, filter boxes, etc. Suitable for the production of cast iron parts. If you have any needs, please do not hesitate to contact us, and let us supply you with the right pouring system to help you produce high-quality iron castings.