What is porous ceramics?

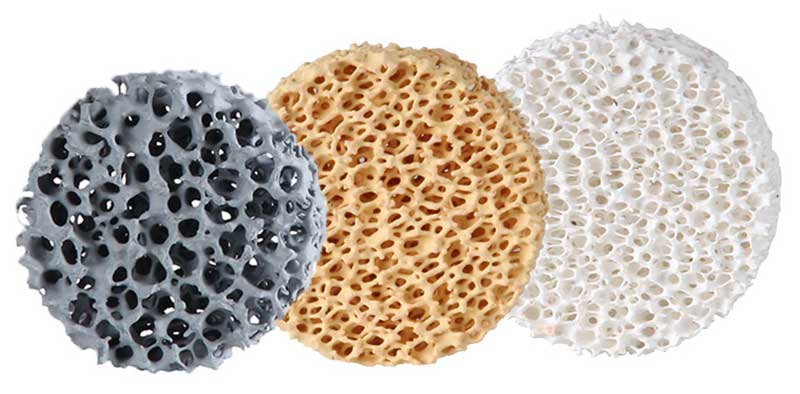

Porous ceramic is a kind of ceramic filter material made of refractory raw material as aggregate, combined with binder and so on through high-temperature sintering. Its structure has a large number of fine pores with controllable pore size. It has the characteristics of high temperature resistance, high pressure resistance, acid resistance and alkali corrosion resistance. It also has the characteristics of uniform pore size and high air permeability.

Therefore, it is widely used as filtration, separation, air distribution and sound-absorbing material.

What are porous ceramics used for?

Using porous ceramics as a filter can be used for upper and lower water purification, mineral water sterilization, oily gas purification, etc. Ceramic filters composed of porous ceramics as filter elements have been more comprehensively promoted and applied in the fields of separation and purification in various industries. Such as liquid-solid, gas-solid separation in the petrochemical industry; aseptic purification treatment in the pharmaceutical and brewing industries; high-temperature flue gas dust removal in the environmental protection industry, etc.

With their unique functional characteristics, ceramic filters have become an irreplaceable product in various separation and purification fields.

What are the characteristics of porous ceramic filters?

Compared with other filter materials, porous ceramics have the following characteristics as a filter material.

- Porous ceramic filter has high porosity, up to more than 60%. The pore size is uniform and easy to control. High filtration precision, suitable for precision filtration of various media.

- Good acid and alkali resistance. It is suitable for the filtration of strong acid, strong alkali and various organic solvents.

- High mechanical strength. Its working pressure can reach 6MPa, and the pressure difference can reach 1MPa.

- High temperature resistance. It has good rapid heating and rapid cooling performance, and the working temperature can reach up to 800°C. Suitable for all kinds of high temperature gas filtration.

- The filter element itself is in a good state of cleanliness, non-toxic, odorless, and no foreign matter falls off, and can be used for aseptic processing operations.

- The filter element has a long service life, and the micropore shape does not change after long-term use, which is convenient for cleaning and regeneration.

SEFU CERAMIC is a production-oriented enterprise that produces porous ceramic materials. Please contact sefunm@hotmail.com if necessary.