If you’ve ever searched for “what are casting defects?” or “how to reduce porosity in castings,” you’ll quickly find that the answer often points back to one critical thing: the gating system. As someone who has spent years in the foundry industry, I can tell you that a well-designed gating system is the unsung hero of a high-quality casting. It’s the difference between a perfect part and expensive scrap.

So, what is meant by a gating system?

In simple terms, think of it as the carefully engineered “plumbing” or “road network” for molten metal. It’s the assembly of channels that guides the liquid metal from the ladle into the mold cavity where your final part solidifies. But it’s far more than just a passive passage—it’s an active hydraulic system that controls the very integrity of your casting.

What are the Functions of a Gating System? The 4 Key Goals

When I design a gating system, I’m not just thinking about getting metal from point A to point B. I’m aiming for four critical objectives to ensure a flawless outcome:

-

Deliver Clean, Inclusions-Free Metal: The system must trap slag, oxides, and other impurities before they can enter the mold cavity. A well-designed system acts as a filter.

-

Ensure Complete and Smooth Filling: It must allow the mold cavity to fill completely with minimal turbulence. Turbulent flow is the enemy, as it causes erosion of the mold and gas defects.

-

Promote Healthy Solidification: This is a point many overlook. The gating system, often working with feeders (risers), helps control how the casting solidifies. We aim for directional solidification, where the remotest parts of the casting solidify first and the gates/risers solidify last, feeding liquid metal to compensate for shrinkage.

-

Be Cost-Effective and Practical: The system should minimize wasted metal (as it becomes scrap) and be easy to remove from the finished casting during the cleaning (fettling) process.

Breaking Down the Gating System in the Manufacturing Process

Where does the gating system fit into the overall manufacturing process? It’s a core part of the pattern-making and mold preparation stage. Once the mold (like a sand mold) is created, the gating system’s channels are already formed within it. After pouring, cooling, and shakeout, the casting is separated from this system. Understanding this flow is key to appreciating its importance.

Key Components of a Gating System in Sand Casting

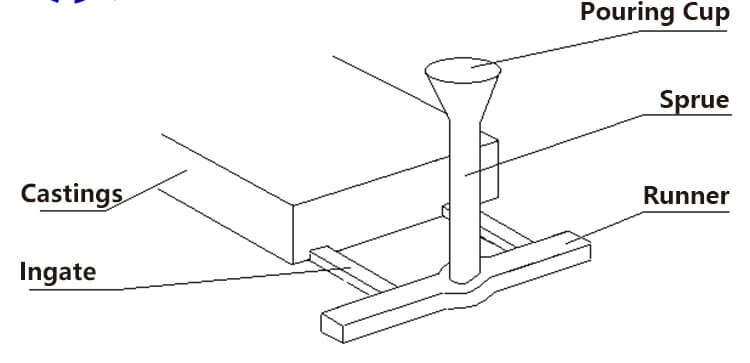

Since sand casting is one of the most common methods, let’s look at the typical components you’ll find in its gating system, in the order the metal flows:

| Component | What It Is & Its Purpose (From My Experience) |

|---|---|

| Pouring Basin/Cup | The entry point. It’s not just a funnel; its shape reduces splash and turbulence the moment metal enters the system. |

| Sprue | The vertical downpipe. A tapered sprue is vital—it prevents air aspiration, which can cause gas porosity. |

| Sprue Well | A small pool at the bottom of the sprue. It absorbs the impact of the falling stream, calming the metal before it turns into the runners. |

| Runner | The main horizontal channels that distribute metal to various parts of the mold. In complex castings, there can be a whole network. |

| Gates | The final, controlled inlets into the mold cavity. We make them smaller to be easily broken off and to act as the final flow control point. |

A simple diagram in your mind would look like this: Pouring Cup -> Sprue -> Sprue Well -> Runner -> Gates -> Mold Cavity.

Common Types of Gating Systems and Their Trade-Offs

In my practice, choosing the right gate type is a fundamental decision. Here are the most common ones:

-

Top Gating: Metal pours directly into the top of the cavity.

-

Pros: Simple, cheap to make.

-

Cons (from experience): The falling metal erodes the mold sand and causes severe turbulence, leading to inclusions and dross. I use this only for very simple, non-critical parts.

-

-

Bottom Gating: Metal enters the cavity from the bottom and fills upwards.

-

Pros: Creates a calm, quiescent fill which is excellent for surface finish and reducing oxides.

-

Cons: The metal cools as it rises, which can create an unfavorable temperature gradient for feeding. The design is also more complex.

-

-

Parting Line Gating: The gates are located along the seam (parting line) between the cope and drag halves of the mold.

-

Why it’s so popular: It’s an excellent balance of simplicity and control. It’s the most widely used type in sand casting for its effectiveness and ease of pattern making.

-

A Note on the Crucial Gating Ratio

For those diving deeper into process engineering, the gating ratio is a key concept. It’s the cross-sectional area ratio of the Sprue : Runner : Gate.

-

A Pressurized System (e.g., 1:0.8:1.2) has the smallest area at the sprue base, creating a “choke” that keeps the system full of metal, preventing air aspiration. This is very common for iron and steel castings.

-

An Unpressurized System has the smallest area at the gates, allowing for a slower, quieter fill but requiring careful design to avoid aspiration.

In conclusion, the gating system is far from an afterthought. It is a foundational element of sound casting design and a primary lever we pull to control quality and yield. Whether you’re a design engineer, a procurement specialist, or a fellow foundry professional, understanding what a gating system in casting is and its critical functions is the first step toward producing and sourcing reliable, defect-free metal components.