In the realm of casting processes, filters play a pivotal role in ensuring the production of high-quality metal components. From removing impurities to regulating metal flow, these filters are indispensable in various casting techniques. One common and essential filter type in casting operations is the ceramic foam filter, renowned for its efficacy in enhancing the quality and integrity of cast products.

The Significance of Filters in Casting Processes

Foundry filters are instrumental in the casting process for their ability to eliminate impurities such as oxides, slag, and non-metallic inclusions from molten metal. By employing filters strategically, manufacturers can significantly improve the overall quality of cast components and reduce the likelihood of defects.

Ceramic Foam Filters: A Key Player in Casting

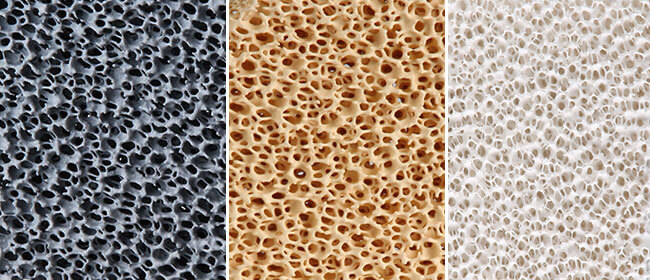

Ceramic foam filters, composed of alumina, silica, zirconia, or a combination thereof, stand out as a popular choice for casting applications. These filters possess a porous structure that efficiently captures impurities present in the molten metal, ensuring a cleaner casting environment. Moreover, ceramic foam filters aid in controlling metal flow, thereby minimizing turbulence and enhancing the final product’s quality.

Diverse Filter Options for Varied Casting Needs

In addition to ceramic foam filters, casting processes may utilize other filter types such as fiber filters and honeycomb ceramic filters, tailored to specific casting requirements. The selection of a filter type is influenced by factors like the type of metal being cast, desired surface finish, and quality standards set for the end product.

Conclusion: Elevating Casting Excellence Through Filter Selection

Filters in the casting process serve as vital components in achieving superior metal components with impeccable quality. By understanding the role of filters, particularly ceramic foam filters, manufacturers can optimize their casting operations, improve product quality, and enhance overall efficiency.

Stay informed about the latest advancements in casting technologies and best practices to stay ahead in the competitive landscape of metal component production.