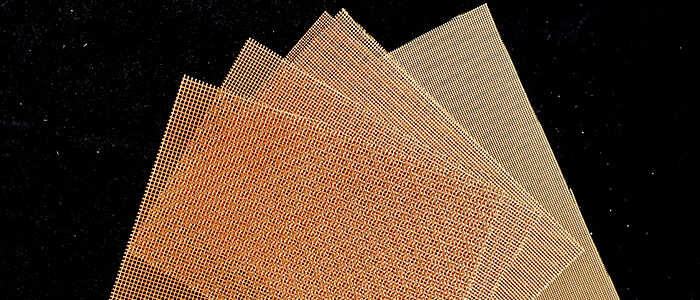

Fiber glass, a versatile material renowned for its strength and durability, finds widespread use in various industrial applications, including the manufacturing of fiberglass casting filter nets in foundries. Understanding the pros and cons of fiberglass is essential for optimizing its utilization in diverse settings.

Pros of Fiber Glass:

- Strength and Durability: Fiberglass exhibits excellent strength properties, making it a reliable choice for applications requiring structural integrity, such as the production of fiberglass mesh filters in foundry operations.

- Corrosion Resistance: The inherent corrosion resistance of fiberglass makes it well-suited for environments where exposure to moisture, chemicals, or harsh conditions is prevalent, ensuring longevity and performance.

- Lightweight Construction: Fiberglass’s lightweight nature facilitates ease of handling and installation, offering a practical solution for applications where weight is a critical factor.

- Customization and Design Flexibility: The moldability of fiberglass enables intricate shaping and customization, allowing for the creation of complex structures tailored to specific requirements, including intricate filter designs in foundry applications.

- Insulation Properties: Fiberglass’s excellent thermal and electrical insulation properties make it an ideal choice for applications where insulation is paramount, maintaining temperature control and electrical safety.

Cons of Fiber Glass:

- Brittleness: While fiberglass is strong, it can be brittle and susceptible to cracking or breakage under excessive stress or impact, necessitating careful handling to prevent damage.

- UV Degradation: Prolonged exposure to ultraviolet (UV) radiation can lead to the degradation of fiberglass, affecting its appearance and mechanical properties over time, necessitating protective coatings in outdoor applications.

- Environmental Concerns: The manufacturing process of fiberglass involves the use of resins and chemicals that may have environmental implications, warranting sustainable practices and waste management strategies.

- Surface Finish Challenges: Achieving a smooth surface finish with fiberglass may require additional finishing processes, such as sanding or painting, to achieve the desired aesthetic appeal and performance.

In conclusion, fiberglass stands as a valuable material in industrial applications, offering a balance of strength, durability, and versatility. Its use in the production of glass fiber casting filter nets exemplifies its importance in enhancing filtration processes in foundries. By weighing the pros and cons of fiberglass, industries can leverage its benefits while mitigating potential drawbacks, ensuring efficient operations and quality outcomes in various industrial settings.