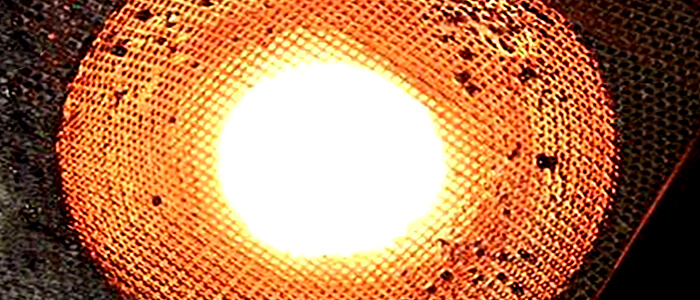

Fiberglass mesh filters have become an essential component in the foundry industry. The mesh filters for foundry are used to improve the quality of castings and increase the productivity of the foundry. These filters are a mesh made of fiberglass, a material known for its strength, durability, and resistance to heat.

The fiberglass mesh filter has several key benefits in the foundry. Firstly, it helps to remove impurities from the metal as it is poured into the mold. It does this by trapping any solid particles in the mesh, allowing the clean molten metal to pass through. This results in a cleaner cast with fewer defects.

Secondly, the mesh filters for foundry help to reduce turbulence in the metal as it enters the mold. This is important as turbulence can cause air bubbles to form, leading to defects in the finished casting. By reducing turbulence, the fiberglass mesh filter helps to ensure a smoother flow of metal into the mold, resulting in a higher-quality casting.

Thirdly, the fiberglass mesh filters for foundry help to ensure a more consistent flow of metal into the mold. This is important as it helps to prevent the formation of hot spots, which can cause the metal to solidify unevenly, resulting in defects in the finished casting. By ensuring a more consistent flow of metal, the fiberglass mesh filter helps to produce castings with a more uniform structure and fewer defects.

Overall, the fiberglass mesh filter is an important component in the foundry industry. The mesh filters for foundry help to improve the quality of castings, increase productivity, and reduce waste. By using fiberglass mesh filters, foundries can produce high-quality castings with fewer defects, reducing the need for rework and boosting their bottom line.