Ceramic foam filters are widely used in the metal casting industry for their ability to improve casting quality and reduce defects. Here are some common applications of ceramic foam filters in metal casting:

Filtration of Molten Metal:

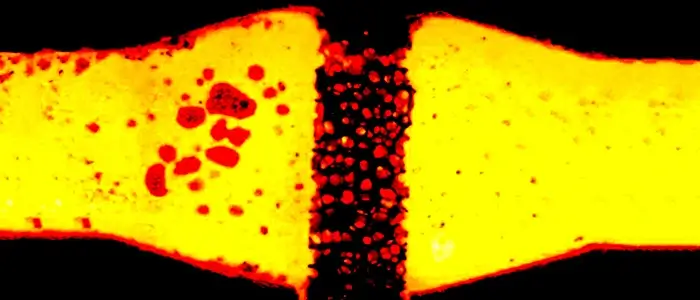

One of the primary applications of ceramic foam filters is the filtration of molten metal. When metal is poured into a mold, it may contain impurities, oxides, and non-metallic inclusions that can negatively impact the final casting quality. Ceramic foam filters are placed in the gating system or mold cavity to capture these impurities as the metal flows through. This helps to ensure a cleaner and more homogeneous metal flow, resulting in castings with improved mechanical properties and reduced defects like porosity and inclusions.

Aluminum Casting:

Ceramic foam filters are extensively used in aluminum casting processes. Aluminum alloys are prone to inclusions and oxides that can lead to casting defects. Ceramic foam filters with suitable pore sizes effectively trap these impurities and prevent their entry into the mold cavity. By using ceramic foam filters, aluminum castings can achieve higher integrity, improved surface finish, and enhanced mechanical properties.

Iron and Steel Casting:

In iron and steel casting, ceramic foam filters play a crucial role in removing impurities like slag, sand particles, and non-metallic inclusions. These filters are capable of withstanding the high temperatures and chemical reactions that occur during the casting process. By using ceramic foam filters, iron and steel foundries can produce castings with reduced defects, improved metallurgical properties, and enhanced surface finish.

Investment Casting:

Investment casting, also known as lost-wax casting, is a precision casting process that requires high-quality molds. Ceramic foam filters are commonly used in investment casting to remove impurities and ensure a smooth and precise metal flow into the mold cavity. They help achieve better surface finish, dimensional accuracy, and intricate detail reproduction in the final castings.

Non-ferrous Metal Casting:

Ceramic foam filters find applications in casting non-ferrous metals like copper, bronze, and brass. These metals often contain impurities that need to be removed to achieve high-quality castings. Ceramic foam filters effectively capture these impurities, resulting in cleaner and more homogeneous metal flow, improved density, and reduced porosity in the castings.

In summary, ceramic foam filters are extensively used in the metal casting industry across various processes and metal types. Their ability to remove impurities, enhance metal flow control, and improve casting quality makes them a vital component in achieving high-integrity castings with fewer defects.