Foundries play a critical role in manufacturing different parts that are used in various industries. From small components used in electronics and consumer goods to large parts used in the automobile and aerospace sectors, foundries produce high-quality parts that are integral to the functioning of many businesses. However, the foundry processes involved in producing these parts can be challenging and complex.

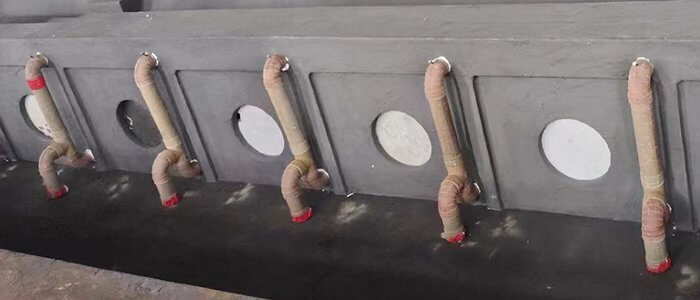

One of the most crucial aspects of foundry processes is the creation of the sprue runner. Sprue runners form a channel for molten metal to flow from the furnace to the molds. The design and construction of these channels are critical for ensuring that the metal flows smoothly and fills the mold correctly. At the same time, it should prevent any impurities from entering the molds, reducing the quality of the final product. In recent years, paper sprue runners have emerged as an excellent and popular alternative to traditional sprue runners.

This article explores what a paper sprue runner is and how it’s used in foundries. We’ll also look at the many benefits that make it the preferred choice of sprue runners in many foundries around the world.

What is a Paper Sprue Runner?

As the name suggests, a paper sprue runner is a channel that’s made of paper to facilitate the flow of molten metal from a foundry furnace to the molds. The paper used in these runners is an eco-friendly, recyclable, and biodegradable material that’s easy to remove and dispose of after casting. The technology behind paper sprue runners is relatively straightforward and is made up of two parts.

The first part is the core material, which forms the channel. It’s a thin, flexible sheet of paper that’s been pre-treated for high-temperature applications. This core material has a unique weave design that creates small pockets of space along the channel’s length. These pockets create small eddies in the flowing molten metal, which helps to remove any impurities that may be present.

The second component is the outer coating material, which is a type of resin. This resin is applied to the surface of the core material, forming a protective layer. This layer has several essential functions, including enhancing the durability of the paper sprue runner, protecting the core material from moisture or humidity, and optimizing the flow of molten metal.

The Benefits of Using Paper Sprue Runner

Paper sprue runners have several advantages that make them the preferred option for foundries around the world. Here are some of the benefits of using paper sprue runners.

Increased Efficiency

Compared to traditional sprue runners, paper sprue runners improve the efficiency of the casting process. The consistent flow channels and uniform cross-sectional area of paper sprue runners ensure smooth, consistent, and predictable meta flow from the furnace to the molds. Paper sprue runners also create less turbulence in the molten metal, which improves metal consistency and casting quality.

Cost-Efficient

Using paper sprue runners can significantly reduce the cost of foundry processes. Traditional sprue runners require intricate and complex designs, which significantly increase the cost of raw materials. On the other hand, paper sprue runners are relatively inexpensive, and costs only a fraction of what traditional sprue runners cost.

Eco-Friendly

Paper sprue runners are an eco-friendly alternative to traditional sprue runners. The paper used in paper sprue runners is recyclable and biodegradable, which means that it’s environmentally friendly and reduces the environmental impact of the casting process.

Ease of Use

Paper sprue runners are straightforward to use and install. The paper material is flexible, allowing for easy shaping to the required form. The core material is treated to withstand high temperatures, while the outer coating material increases the paper runner’s durability. Installing paper sprue runners requires fewer personnel and less time, making the foundry processes more efficient.

How to Use Paper Sprue Runner

Using paper sprue runners is relatively straightforward and requires a few essential steps. Here’s a step-by-step guide on how to use paper sprue runners.

Step 1: Design the Sprue Runner System

The first step towards using paper sprue runners involves designing the desired sprue runner system. This design process includes determining the dimensions of the sprue runners, their length, the number of runners required, and the angle of their installation.

Step 2: Cut the Paper Core Material

Once the sprue runner system design has been finalized, the next step is to cut the paper core material to the required length. Cutting the core material involves using a precision cutting tool such as a sharp blade or scissors.

Step 3: Form the Sprue Runner Channel

Once the paper core material has been cut to the required length, it’s time to shape the sprue runner channel using a mandrel. A mandrel is a tool used to shape and form the paper material into the desired shape and dimensions.

Step 4: Apply the Resin Coating

After forming the sprue runner channel, the next step is to apply the resin coating. Resin coating involves applying a protective layer of resin to the paper runner to increase its durability, make it moisture-resistant, and optimize the flow of molten metal.

Step 5: Dry and Curing

After applying the resin coating, the paper sprue runner needs to be left to dry and cure. This process can take anywhere from a few hours to a day, depending on the type of resin used and the environmental conditions.

Step 6: Installing the Paper Sprue Runner

Once the paper sprue runner has dried and cured, the final step is to install it in the foundry system. This process involves attaching the runner to the furnace and connecting it to the molds.

Conclusion

Using paper sprue runners can significantly improve foundry processes’ efficiency, reduce costs, and help reduce the environmental impact of casting processes. This guide has outlined the many benefits of using paper sprue runners and provided a step-by-step guide on how to use them in foundries. Therefore, foundries can incorporate paper sprue runners as a cost-efficient and eco-friendly option for their casting needs.