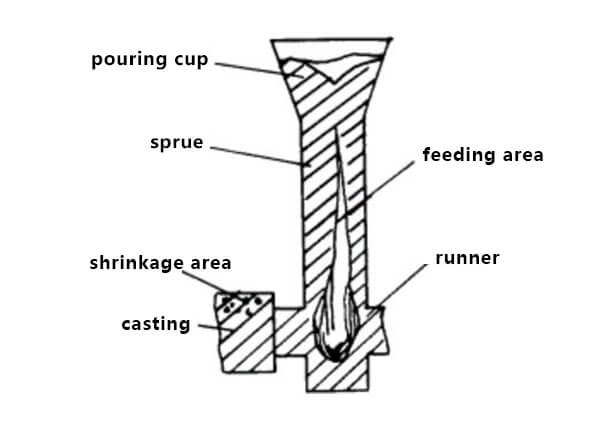

In metal casting, plastic injection molding, and various other casting processes, the sprue plays a crucial role. It serves as a channel through which liquid material is guided into the mold cavity from the pouring basin or inlet. The sprue is instrumental in ensuring the smooth and uniform flow of material into the mold cavity, ultimately shaping the final product.

What is Sprue in Casting?

Sprue plays a pivotal role in casting. It serves as a conduit for guiding and controlling the flow of material, allowing for even filling of the mold cavity. This helps reduce defects such as air pockets and incomplete material filling, ensuring the quality of the final product.

What is Sprue and Runner in Casting?

In casting processes, in addition to the sprue, there is another essential element—the runner. The runner is a channel that extends from the sprue, guiding the material to various parts of the mold. It aids in distributing the material evenly throughout the mold, ensuring thorough filling of the entire part.

The Difference Between a Sprue and a Runner

Sprue and runner play different roles in casting. The sprue is the main channel through which material flows from the inlet into the mold. Once the material solidifies, the sprue is typically removed. On the other hand, the runner is a secondary channel branching off from the sprue, guiding the material to different areas of the mold. Their combined action ensures uniform material filling and the quality of the final product.

Well-designed sprue and runner systems are critical in casting processes. They not only influence the quality of the final product but also impact production efficiency and costs. By optimizing the design of sprue and runner systems, manufacturers can enhance casting process efficiency, reduce waste, and lower production costs.

In conclusion, the sprue plays a vital role in the casting process. Understanding the design principles of sprue and runner systems and their functions in casting processes is crucial for ensuring the quality of the final product. By optimizing the design of sprue and runner systems, manufacturers can improve production efficiency, reduce costs, and produce high-quality cast products.