The ceramic porous filter has emerged as highly efficient filtration solution in recent years, catering to diverse industries. These filters are designed to effectively separate solid particles from liquids or gases, making them indispensable for applications like water purification, air pollution control, and industrial processes. However, despite their significant advantages, the ceramic porous filter is relatively new to the market, leading to a lack of awareness among customers regarding their field of use, purchasing considerations, and manufacturing processes.

In recent times, as society progresses, more and more customers are actively seeking more efficient filtration products, gradually opening up the market for ceramic porous filters. With this increased interest, many customers encounter various problems and questions. As a provider of these filters, I am dedicated to addressing these concerns and constantly improving my knowledge in the field.

Introduction to Ceramic Porous Filter:

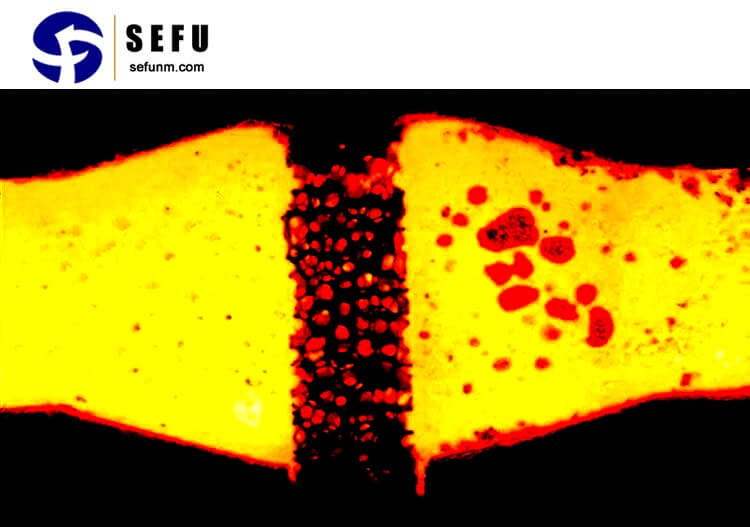

Ceramic porous filters have gained attention as a result of advancements in materials science and manufacturing techniques. These filters are composed of a ceramic material, such as alumina or silicon carbide, which possesses controlled porosity. The structure of the ceramic porous filter is characterized by interconnected pores that allow for the passage of fluids while retaining solid particles. The intricate network of pores within the filter material enables efficient filtration by employing several mechanisms.

Filtration Mechanisms of Ceramic Porous Filter:

The filtration process of ceramic porous filters relies on multiple mechanisms that work together to achieve effective separation of solid particles from fluids. The primary filtration mechanisms employed by ceramic porous filters include sieving, adsorption, and electrostatic attraction.

- Sieving:

Ceramic porous filters act as sieves, physically trapping solid particles larger than the pore size within their structure. The size of the pores can be tailored during the manufacturing process to suit specific filtration requirements. This sieving action ensures that particles above a certain size are effectively removed from the fluid passing through the filter.

- Adsorption:

In addition to sieving, ceramic porous filters also utilize adsorption to remove smaller particles and dissolved impurities. The porous structure of the ceramic material provides a large surface area, allowing for the adsorption of contaminants onto the filter’s surface. This adsorption process effectively removes particles and impurities that may have passed through the sieving mechanism.

- Electrostatic Attraction:

Certain ceramic materials used in porous filters possess electrostatic properties that aid in the filtration process. Charged particles present in the fluid can be attracted to the oppositely charged filter material, facilitating their removal from the fluid stream. This mechanism is particularly effective in capturing charged particles that may be challenging to remove using only sieving or adsorption.

Advantages of Ceramic Porous Filter:

Ceramic porous filters offer several advantages over traditional filtration methods, making them a preferred choice in various industries. Some key advantages include:

- High Filtration Efficiency:

Ceramic porous filters are renowned for their exceptional filtration efficiency, thanks to their precisely controlled pore sizes and multiple filtration mechanisms. They can effectively remove particles of various sizes, ensuring cleaner and purer fluids.

- Chemical Resistance:

Ceramic materials used in the manufacturing of these filters exhibit excellent chemical resistance. This property allows them to withstand exposure to a wide range of aggressive chemicals, making them suitable for diverse applications where filtration of corrosive fluids is necessary.

- Thermal Stability:

Ceramic porous filters can withstand high temperatures without significant degradation, making them ideal for applications involving hot fluids or processes. Their thermal stability ensures that filtration performance remains consistent even under challenging operating conditions.

- Longevity and Durability:

Ceramic porous filters are known for their durability and longevity. They can withstand high-pressure differentials and repeated cleaning cycles without compromising their structural integrity or filtration efficiency. This longevity translates into reduced maintenance costs and increased overall efficiency.

Promoting Awareness and Addressing Customer Queries:

As mentioned earlier, the market for ceramic porous filters is still relatively new, and customers may have limited knowledge about their applications, purchasing considerations, and manufacturing processes. To promote the adoption of these filters and assist customers, it is crucial to address their questions and concerns. As a provider of ceramic porous filters, I am committed to actively engaging with customers, answering their queries, and sharing my knowledge and expertise. This open dialogue not only helps customers make informed decisions but also contributes to my continuous learning and improvement in the field.

Conclusion:

Ceramic porous filters represent a significant advancement in filtration technology, offering high efficiency, chemical resistance, thermal stability, and durability. By understanding their working mechanisms, including sieving, adsorption, and electrostatic attraction, users can appreciate the exceptional filtration capabilities of these filters. Although the market for ceramic porous filters is still relatively new, increased customer demand for more efficient filtration products is gradually opening up opportunities. By addressing customer queries, promoting awareness, and continuously advancing knowledge in the field, we can foster the wider adoption of ceramic porous filters and unlock their full potential in various industries.