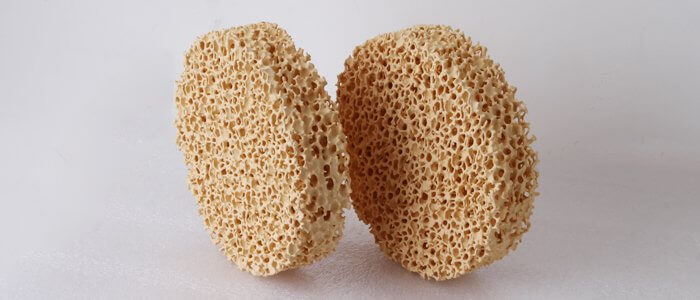

Zirconia ceramic foam filters are critical components in the casting industry, used to improve the quality of molten metal by removing impurities. In recent years, the trade market for these filters in Korea has seen notable growth due to the country’s thriving manufacturing and foundry industries. Let’s explore the trade market trends, application areas, and the importance of zirconia ceramic foam filters in South Korea.

Trade Market Trends of Zirconia Ceramic Foam Filters:

Increased Export: Korea has been a significant player in the global foundry and metalworking industry, and the export of zirconia ceramic foam filters has grown steadily. The filters are sought after in international markets, and their export contributes to the country’s trade balance.

Growing Demand: The rising demand for high-quality castings in various industries, including automotive, aerospace, and electronics, has driven the demand for zirconia ceramic filters. Korea’s foundry sector, which supplies these industries, has thus witnessed an increasing requirement for these filters.

Market Competitiveness: Korean manufacturers have invested in research and development to produce advanced zirconia ceramic filters. This has made them competitive in the global market, as they can offer high-quality filters at a reasonable price.

Application Areas of Zirconia Ceramic Foam Filters:

Automotive Industry: Zirconia ceramic foam filters are extensively used in the automotive industry for casting engine components, such as cylinder heads, engine blocks, and exhaust manifolds. The filters help ensure the castings are free from impurities, enhancing the durability and performance of automobile engines.

Aerospace Industry: Aerospace applications demand the highest quality castings to ensure safety and performance. Zirconia ceramic filters are crucial in the aerospace sector, especially for casting critical components like turbine blades, aircraft engine parts, and structural components.

Electronics and Semiconductors: In the electronics industry, zirconia ceramic filters are employed in the casting of aluminum and magnesium components used in electronic devices. Ensuring purity is essential to maintain the integrity of these components.

General Foundry Operations: Apart from specific industries, zirconia ceramic foam filters find use in general foundry operations. They help produce clean and high-integrity castings for a wide range of applications, from machinery parts to architectural components.

Importance:

Quality Enhancement: Zirconia ceramic foam filters play a crucial role in improving casting quality. By removing impurities and unwanted particles from the molten metal, they contribute to the production of high-quality and defect-free castings.

Cost Savings: While zirconia filters require an initial investment, their use results in cost savings by reducing the need for rework or the scrap of defective castings. The filters ensure that castings meet the required specifications on the first attempt.

Industry Competitiveness: Korean foundries that utilize zirconia filters can offer high-quality castings that meet international standards. This enhances the country’s competitiveness in global markets and attracts international clients.

Safety and Environmental Compliance: Ensuring clean and safe casting processes is crucial for both worker safety and environmental compliance. Zirconia filters help in achieving these goals by reducing the risks associated with impurities in castings.

In conclusion, the trade market for zirconia ceramic foam filters in South Korea has seen growth in recent years due to increased demand in various industries. These filters are vital in enhancing casting quality, reducing costs, maintaining competitiveness, and ensuring safety and environmental compliance, making them an indispensable component in the foundry industry.