Think about the last time you brewed a perfect cup of coffee. The filter was essential, wasn’t it? It trapped the grounds while allowing the rich, flavorful liquid to pass through. Now, imagine that same principle applied on an industrial scale, where the stakes involve product integrity, equipment longevity, and operational safety. This is process filtration, a vital step in manufacturing that removes unwanted particles and contaminants from liquids and gases to ensure final products meet stringent quality and safety standards.

In metalcasting, the choice of a filtration system is not a minor detail—it is a decisive factor that separates a high-quality, reliable casting from a defective one. The wrong filter can lead to inclusions, porosity, and weakened mechanical properties, resulting in costly scrap, rework, and customer returns. This guide will explore the fundamental types of industrial filtration and their applications, with a focused lens on how advanced solutions, particularly ceramic foam filters, solve core challenges in foundries worldwide.

Understanding Core Filtration Technologies

At its heart, filtration is about separation. Different mechanisms are employed based on the nature of the contaminant and the desired outcome. For foundry engineers, understanding these core types is key to selecting the right tool for the job.

Depth Filtration: The Three-Dimensional Barrier

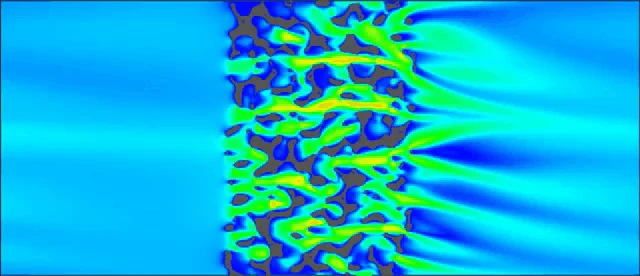

Unlike a sieve that works only on the surface, depth filtration captures particles throughout the entire volume of a porous material. The filter medium, often made of fibrous, granular, or sintered materials, creates a maze of winding channels. As the fluid passes through, particles are trapped by various mechanisms—not just size exclusion, but also through adsorption and impaction within the tortuous path.

This technology is prized for its high dirt-holding capacity. It can handle liquids with a significant solid load and is frequently used as a pre-filtration step to protect more sensitive, final-stage filters. In many ways, a ceramic foam filter operates on a powerful depth filtration principle, providing a three-dimensional network to capture impurities within its structure.

Surface (or Sieve) Filtration: Precision at the Interface

This is the most intuitive type of filtration, where separation occurs right at the surface of the medium. Particles larger than the pore size are retained on the surface, while smaller ones pass through. Membrane filters used for achieving sterile liquids are a classic example. While excellent for final polishing, surface filters can clog quickly if the fluid has a high particulate load, which is why they are often preceded by a depth filter.

Crossflow Filtration: The Continuous Flow Solution

In crossflow filtration, the fluid stream flows tangentially across the filter membrane instead of perpendicularly through it. This sweeping action prevents the build-up of a filter cake, allowing for continuous, long-term operation with less fouling. This method is common in industries like biotechnology and dairy processing. While less common in mainstream metal flow applications, the principle informs advanced filtering and degassing systems.

Filtration’s Paramount Role in the Foundry

In a foundry, the “fluid” is often over 700°C molten metal, and the “contaminants” are non-metallic inclusions like slag, oxides, and refractory fragments. Their presence is a primary cause of defects. The right industrial filter system addresses several critical needs:

-

Protecting the Final Product: This is the primary goal. Filters remove harmful inclusions that cause machining tool wear, surface defects, and reduced mechanical performance in the final cast component.

-

Optimizing Process Efficiency: A clean metal stream pours more smoothly and predictably. Filters can act as a flow rectifier, reducing turbulence and minimizing the entrapment of air and gases, which leads to porosity.

-

Improving Yield and Profitability: By drastically reducing scrap and rework rates, filtration directly boosts operational efficiency and material utilization. Documented case studies show that effective filtration can lower scrap rates by 10% or more.

Why Ceramic Foam Filters Are the Foundry Standard

Among the various filter types available—including fiberglass mesh and direct-pour ceramic filters—foam ceramic filters have become the preferred solution for high-quality ferrous and non-ferrous casting. Here’s why they excel:

They are engineered to perform under the extreme conditions of a foundry. Made from materials like silicon carbide (SiC), alumina (Al₂O₃), and zirconia (ZrO₂), they offer exceptional resistance to thermal shock and erosion by molten metal.

Their unique, three-dimensional reticulated structure provides a vast surface area within a compact volume. This design creates a deep-bed filtering effect that is extraordinarily effective. As molten metal passes through, it benefits from three key actions:

-

Cake Filtration: Larger inclusions are trapped at the filter entrance, forming a cake that itself aids in filtering finer particles.

-

Depth Trapping: Mid-size particles are captured within the intricate internal network of the filter.

-

Flow Rectification: The filter transforms a turbulent metal stream into a more laminar, steady flow, which prevents re-oxidation and vortex formation.

The result is a dramatically cleaner melt. Tests demonstrate that advanced ceramic foam filters can remove over 95% of non-metallic inclusions. This leads to tangible improvements: a 10-15% increase in mechanical properties of the casting, extended tool life during machining, and significantly improved surface finish.

Choosing the Right Filter for Your Application: An SF-Foundry Perspective

Selecting a filter isn’t a one-size-fits-all decision. At SF-Foundry, we guide our clients through a selection process based on their specific metal, casting method, and quality goals. Here are the key considerations, informed by years of industry experience:

-

Metal Type & Temperature: Aluminum, ductile iron, and superalloys all have different chemical interactions and pouring temperatures. We match the filter chemistry (SiC, Alumina, Zirconia) to be inert and stable in your melt.

-

Inclusion Load & Size: The expected amount and size of debris determine the required porosity (measured in Pores Per Inch or PPI) and filter thickness. A higher dirt load might require a coarser pre-filter or a thicker filter to maximize capacity.

-

Pouring Method & Flow Rate: Whether using automatic pouring systems, ladles, or gating systems, the metal flow rate must be compatible with the filter’s size to avoid choking or excessive turbulence.

-

Criticality of the Casting: Aerospace components demand a different level of filtration fidelity compared to some municipal castings. The choice between standard and high-performance filters hinges on this.

A Practical Insight: One of the most common lessons from the field is the importance of proper installation and preheating. A cold filter can chill the metal, cause premature freezing, and even lead to dangerous thermal shock and filter fracture. Always preheat filters to recommended temperatures to ensure smooth metal flow and filter integrity.

Beyond Casting: The Versatility of Ceramic Foam

While metal filtration is our core focus, the inherent properties of ceramic foam—high temperature resistance, high surface area, and structural permeability—make it invaluable in other demanding industrial applications. Our materials are also engineered for use as:

-

High-Temperature Gas Filters: Removing particulate matter from exhaust streams in chemical plants or incinerators.

-

Catalyst Supports: Providing a stable, porous substrate for catalytic reactions in pollution control systems (like automotive catalytic converters) and chemical processing.

-

Thermal and Acoustic Insulators: Serving in high-temperature furnaces and environments where heat management is critical.

Conclusion

Viewing filtration as a mere consumable expense is a missed opportunity. The data is clear: implementing the correct, high-performance filtration system is a strategic investment that pays dividends through reduced scrap, lower machining costs, fewer customer quality claims, and an enhanced reputation for reliability.

As a leading manufacturer of Silicon Carbide, Alumina, and Zirconia Ceramic Foam Filters, SF-Foundry is committed to providing more than just products. We partner with foundries to deliver clean metal solutions that drive quality and profitability.

Ready to filter out your quality problems? Contact SF-Foundry’s technical team today for a consultation. Let us analyze your specific metal, process, and challenges to recommend the optimal filtration solution that will help you cast with greater confidence and efficiency.