Introduction:

In the intricate world of metal casting, the quality of the final product hinges on various factors, with iron filtration playing a pivotal role in ensuring superior casting outcomes. As foundries strive for operational excellence and product integrity, the implementation of effective iron filtration systems stands as a cornerstone for success. This blog delves into the significance of iron filtration in metal casting processes, highlighting its impact on product quality, operational efficiency, and industry best practices.

The Importance of Iron Filtration in Metal Casting:

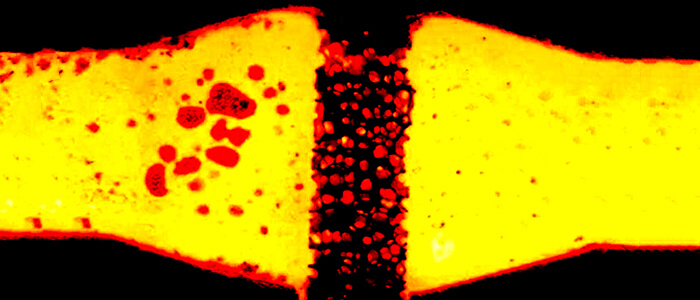

Iron filtration serves as a critical step in the metal casting process, primarily aimed at removing impurities and enhancing the purity of molten metal. By effectively capturing and eliminating contaminants such as oxides, slag, and non-metallic inclusions, iron filtration plays a key role in improving the mechanical properties and surface finish of cast components. Moreover, proper filtration helps prevent casting defects, reduces scrap rates, and enhances the overall quality of the final product.

Types of Iron Filtration Systems:

Foundries employ various types of iron filtration systems to cater to diverse casting requirements. Ceramic foam filters, widely recognized for their high filtration efficiency and heat resistance, are commonly used in both ferrous and non-ferrous metal casting applications. Additionally, mesh filters offer cost-effective solutions for capturing impurities and ensuring clean molten metal for casting.

Benefits of Efficient Iron Filtration:

Efficient iron filtration brings a multitude of benefits to foundries, including:

Enhanced Casting Quality: Clean molten metal results in defect-free castings with improved mechanical properties.

Reduced Rework and Scrap Rates: Effective filtration minimizes the occurrence of defects, leading to lower rework and scrap costs.

Improved Operational Efficiency: Streamlined casting processes and reduced downtime contribute to enhanced overall foundry productivity.

Best Practices for Iron Filtration:

To optimize iron filtration in metal casting processes, foundries should adhere to the following best practices:

- Regular Maintenance: Routinely inspect and maintain filtration systems to ensure optimal performance.

- Proper Sizing: Select filters based on the specific requirements of the casting process to achieve desired filtration efficiency.

- Monitoring and Control: Implement monitoring systems to track filtration performance and make adjustments as needed.

- Training and Skill Development: Provide training to personnel on proper handling and installation of filtration systems to maximize effectiveness.

Conclusion:

In conclusion, iron filtration stands as a cornerstone of successful metal casting operations, significantly impacting product quality, operational efficiency, and overall foundry performance. By implementing efficient iron filtration systems and adhering to industry best practices, foundries can elevate their production standards, reduce costs, and achieve excellence in the competitive landscape of metal casting. Embracing the importance of iron filtration is not just a choice but a necessity for foundries aiming to thrive in the dynamic and demanding world of metal manufacturing.