Machine tool castings are a vital aspect of manufacturing as they serve as the skeleton of many machines and devices. The casting process involves pouring molten metal into a hollow mold to take a specific shape and size. The quality of casting is determined by the integrity of the mold and the metal used. Casting defects such as porosity, sand inclusions, and slag inclusions can affect the functionality of the final product. Hence, several methods have been developed to eliminate these defects, one of which involves the use of Ceramic Foam Filters.

This article will discuss the casting of machine tool castings, why Ceramic Foam Filters are essential in the casting process, and their application and market analysis.

Casting of Machine Tool Castings

The casting of machine tool castings involves using various casting methods such as sand casting, permanent mold casting, die casting, and lost foam casting. The metal alloys used in machine tool castings include aluminum, magnesium, copper, zinc, iron, and steel. Before pouring the molten metal into the mold, the mold cavity is coated with a refractory material to prevent the mold from fusing with the metal.

The molten metal is then poured into the mold and let to cool and solidify. The casting is then removed from the mold, and excess materials such as sprues and runners are cut off. The final step involves finishing the casting by grinding, polishing, or machining.

Why Ceramic Foam Filters are Essential in Casting Machine Tool Castings

Casting defects such as porosity, sand inclusions, and slag inclusions occur due to various reasons such as impurities in the molten metal, turbulence during the pouring process, and the reaction of the molten metal with the mold material. These defects can weaken the casting’s mechanical properties, affect its surface finish, and reduce its lifespan.

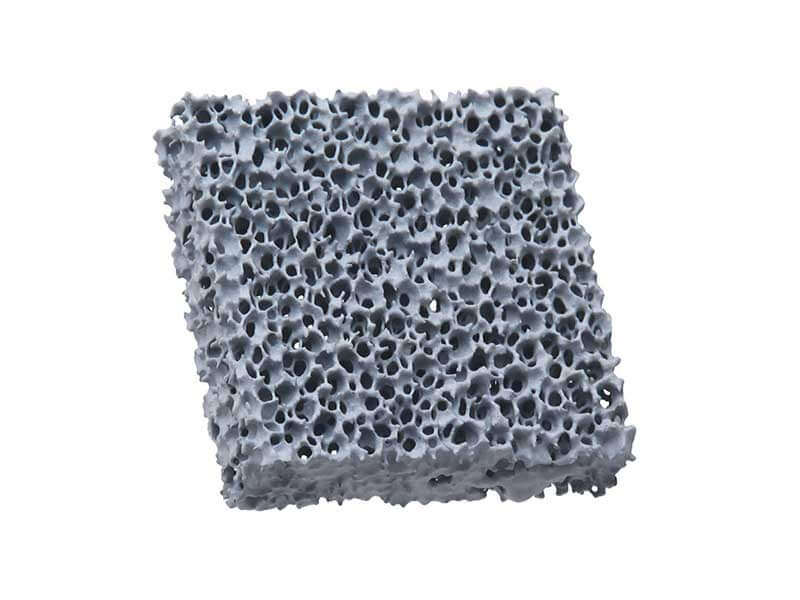

Using Ceramic Foam Filters in the casting process can help eliminate these defects. Ceramic Foam Filters consist of ceramic foam that traps impurities in the molten metal as it flows through the filter. The filter also prevents turbulence during the pouring process and reduces the reaction of the molten metal with the mold material.

The Application of Ceramic Foam Filters in Machine Tool Castings

Ceramic Foam Filters are used in various casting methods such as sand casting, investment casting, and lost foam casting. The filters also come in different shapes and sizes depending on the metal alloy used in the casting process. For instance, aluminum-based castings require a different filter than steel-based castings.

![]()

Ceramic Foam Filters have several advantages over other filtering materials such as sand and ceramic filters. They have a higher filtration efficiency, reduce metal turbulence in the mold, and can be reused several times, reducing waste.

Market Analysis of Ceramic Foam Filters in Machine Tool Castings

The market for Ceramic Foam Filters is expected to grow significantly in the next few years due to the increasing demand for high-quality castings. The automotive and aerospace industries account for the largest share of the foam ceramic filter market due to the critical nature of the castings used in these industries.

According to a report by MarketsandMarkets, the global foam ceramic filter market was valued at USD 1.1 billion in 2020 and is expected to grow to USD 1.7 billion by 2025. The report attributes the market growth to the increasing demand for lightweight and fuel-efficient automobiles, the growth of the aerospace industry, and the increasing adoption of 3D printing technology in the casting process.

Conclusion

Ceramic Foam Filters are an essential component in the casting of machine tool castings. They help prevent casting defects such as porosity, sand inclusions, and slag inclusions, and improve the mechanical properties and surface finish of the final casting. The market for Ceramic Foam Filters is expected to grow in the coming years due to the increasing demand for high-quality castings in various industries. Manufacturers and researchers should continue to develop and optimize the foam ceramic filter technology to meet the ever-increasing demands of the market.