Introduction:

Foundry is an industry that deals with producing metallic parts by melting and pouring metals into molds. Depending on the type of metal and the product that is being produced, the foundry process can produce smoke, dust, and other airborne pollutants, which can be harmful to the human body as well as the surrounding environment. To minimize the effects of these pollutants, it is essential to use filtration systems that can capture and remove these pollutants before they escape into the air. One such system that has gained popularity in recent years is the fiberglass mesh filter.

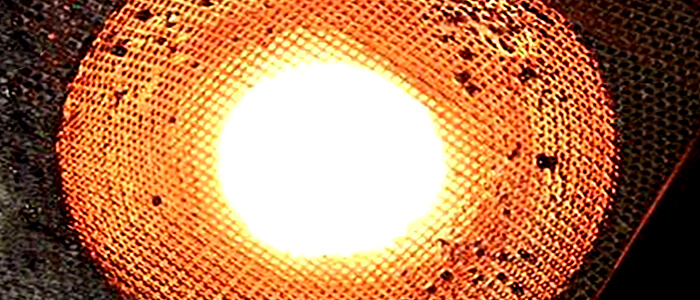

Fiberglass mesh filter is a type of air filter that is made of woven fiberglass threads that are coated with a resin binder. The filter is designed to capture particulate matter, including dust smoke, and other airborne pollutants. The use of fiberglass mesh filters in the foundry industry has increased significantly in recent years due to their high filtration efficiency, low-pressure drop, and long service life.

Application of Fiberglass Mesh Filter in Foundry Markets:

The application of fiberglass mesh filters in foreign foundry markets has been growing steadily over the last few years. The filter has been widely adopted in countries such as the United States, Germany, France, Japan, and South Korea, among others.

The growing demand for fiberglass mesh filter can be attributed to its many benefits over traditional filtration systems, such as:

Higher Filtration Efficiency:

Fiberglass mesh filters are highly efficient in capturing particulate matter, including fine dust and smoke particles. The filters have a high MERV rating, which indicates their effectiveness in removing airborne pollutants.

Low Pressure Drop:

Fiberglass mesh filters have a low-pressure drop, which means that they do not restrict the flow of air through the system. This ensures that the system operates efficiently and reduces energy consumption.

Long Service Life:

Fiberglass mesh filters have a long service life, which means that they do not need to be replaced frequently. This reduces the maintenance costs of the system.

Export Situation:

The export situation of fiberglass mesh filters has been growing steadily in recent years. China is one of the leading exporters of fiberglass mesh filters, accounting for over 50% of the global production. The increasing demand for fiberglass mesh filters in foreign markets has created a lucrative export opportunity for Chinese manufacturers. The export of fiberglass mesh filters from China has been driven by several factors, such as:

Competitive Pricing:

Chinese manufacturers offer fiberglass mesh filters at competitive prices, which makes them an attractive option for foreign buyers.

Quality Standards:

Chinese manufacturers adhere to strict quality standards, which ensure that the products meet the requirements of foreign buyers.

Large Scale Production:

Chinese manufacturers can produce fiberglass mesh filters in large quantities, which makes them capable of meeting the growing demand of foreign markets.

Conclusion:

In conclusion, the application of fiberglass mesh filters in the foundry industry has been growing steadily over the last few years. The filter has been widely adopted in foreign markets due to its many benefits over traditional filtration systems. The increasing demand for fiberglass mesh filters has created a lucrative export opportunity for Chinese manufacturers. The export situation of fiberglass mesh filters from China has been driven by competitive pricing, adherence to quality standards, and large-scale production capabilities. With the growing demand for fiberglass mesh filters in foreign markets, the export situation is expected to continue to improve in the coming years.