In recent years, the international market for ceramic foam filters has witnessed substantial growth, and China has emerged as a key player in meeting the global demand for this specialized product.

The Rise of Ceramic Foam Filters:

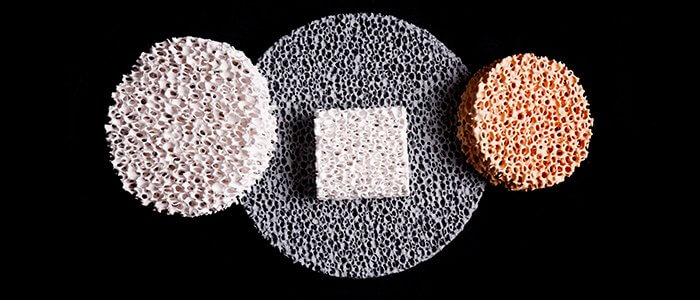

Ceramic foam filters have become indispensable in industries such as metal casting and foundries due to their unique properties. These filters, typically made from alumina or silicon carbide, offer high-temperature resistance, excellent thermal shock resistance, and the ability to efficiently remove impurities from molten metals. As a result, they play a critical role in enhancing the quality of castings and improving overall production efficiency.

International Market Evaluation:

The international market for ceramic foam filters has seen a significant uptick in demand, driven by the expansion of metal casting industries across the globe. Countries with burgeoning manufacturing sectors, particularly those involved in the production of aluminum, steel, and other metal alloys, have sought high-quality ceramic filters to improve the integrity of their castings.

Why China Dominates Ceramic Foam Filters Exports:

Quality Standards and Expertise:

China has developed a reputation for producing high-quality ceramic foam filters that meet or exceed international standards. Chinese manufacturers have invested in research and development, ensuring that their products not only comply with industry norms but also incorporate the latest advancements in material science and manufacturing techniques.

Cost-Effectiveness:

Chinese manufacturers benefit from economies of scale and efficient production processes, allowing them to offer competitive pricing for ceramic foam filters. This cost-effectiveness has been a significant factor in attracting international buyers looking for reliable and affordable solutions to improve their metal casting processes.

Capacity and Scale of Production:

China’s manufacturing capabilities are immense, and the country has the infrastructure to produce ceramic filters on a large scale. This ensures a stable and consistent supply, crucial for industries that rely on these filters for uninterrupted production.

Adaptability to Customization:

Chinese manufacturers often provide a range of customization options to cater to the specific needs of different industries. The ability to tailor ceramic foam filters to meet unique requirements has contributed to China’s appeal as a preferred supplier in the international market.

Global Supply Chain Integration:

China has integrated itself into the global supply chain, facilitating smooth logistics and distribution. This interconnectedness ensures that countries importing ceramic filters from China can rely on efficient shipping and timely deliveries.

Conclusion:

The recent evaluation of ceramic foam filters in the international market underscores their crucial role in enhancing metal casting processes globally. China’s dominance in the export of these filters can be attributed to a combination of quality standards, cost-effectiveness, production scale, adaptability, and seamless integration into the global supply chain. As industries continue to prioritize the improvement of their casting practices, China is likely to maintain its pivotal role in meeting the growing demand for ceramic filters worldwide.