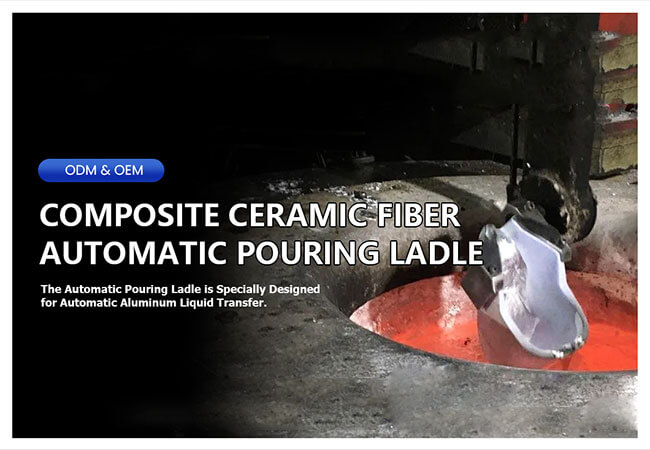

In the competitive landscape of aluminum casting, consistency is not just a goal—it is the absolute foundation of profitability and reputation. At the heart of achieving this relentless consistency lies a pivotal piece of technology: the Automatic Pouring Ladle. More than a simple tool for transferring molten metal, it is the central nervous system of a precision-driven casting process, dictating the final quality of every single component produced.

For foundries like SF-Foundry, integrating and mastering this technology is a strategic imperative. It represents the shift from artisanal skill to controlled, repeatable science. This article delves into the multifaceted importance of the automatic pouring ladle and why its performance is non-negotiable for any foundry targeting excellence.

The Engine of Unmatched Consistency and Quality

Human variability is the natural enemy of casting consistency. Manual pouring introduces fluctuations in pour speed, pour height, and metal temperature—all of which directly lead to defects like cold shuts, mistruns, and gas porosity.

The automatic pouring ladle eliminates this variability. Programmed for each specific mold, it delivers an identical pour weight, speed, trajectory, and temperature, cycle after cycle. This robotic precision ensures:

-

Uniform Metallurgical Properties: Consistent thermal history leads to predictable and homogeneous grain structure.

-

Dramatically Reduced Scrap Rates: Eliminating common pouring-related defects directly boosts yield and profitability.

-

Superior Surface Finish: A smooth, controlled pour minimizes turbulence and oxide entrapment.

The Driver of Operational Efficiency and Productivity

Modern casting lines are high-speed systems. A slow or inconsistent pouring process becomes the bottleneck that limits overall equipment effectiveness (OEE).

Automatic pouring ladles are engineered for speed and synchronization. They work in seamless concert with molding machines, core setters, and extractors.

-

Optimized Cycle Times: Fast, precise movements and minimal dwell time maximize cycles per hour.

-

Uninterrupted Production: Capable of 24/7 operation, they enable lights-out production shifts, maximizing asset utilization.

-

Reduced Downtime: Unlike manual operations, they do not require breaks, creating a continuous, predictable production flow.

The Guardian of Workplace Safety

The handling of molten aluminum at temperatures exceeding 700°C (1292°F) is inherently hazardous. Manual pouring exposes operators to risks of burns, fume inhalation, and ergonomic injuries.

Deploying an automatic pouring system is one of the most significant safety investments a foundry can make.

-

Removes Personnel from Hazard: Operators manage the process from a safe distance via control panels.

-

Ergonomic Risk Elimination: It eliminates the strenuous physical labor of handling heavy ladles.

-

Predictable Process Control: Automated systems follow a strict, repeatable path, reducing the chance of accidental spills or collisions.

The Catalyst for Advanced Process Control and Data

In the era of Industry 4.0, data is king. Modern automatic pouring ladles are data hubs, equipped with integrated load cells, thermocouples, and position sensors.

This transforms pouring from an action into a measurable, analyzable, and optimizable process parameter. Foundries like SF-Foundry leverage this data to:

-

Enable Real-Time Monitoring: Track pour weight and temperature for every shot, with automatic rejection of out-of-specification pours.

-

Facilitate Predictive Maintenance: Monitor system performance to schedule maintenance before failures occur.

-

Create a Digital Process Fingerprint: Trace any casting batch back to its exact pouring parameters for full quality assurance and continuous improvement.

The Key to Material Efficiency and Cost Control

Wasted metal is wasted profit. Over-pouring to ensure mold fill is an expensive and outdated practice.

Automatic ladles provide sub-gram accuracy in dosing. By delivering the exact amount of metal required—no more, no less—they directly impact the bottom line:

-

Increased Yield: More castings produced per ton of molten metal.

-

Reduced Energy Consumption: Less metal poured means less metal to melt and hold at temperature.

-

Lower Rework and Scrap Costs: Consistent quality means fewer components destined for the remelt furnace.

Conclusion

For forward-thinking aluminum foundries, the automatic pouring ladle is no longer optional equipment. It is the critical differentiator that separates standard operations from world-class manufacturing.

It is the point where quality, speed, safety, and intelligence converge in the casting process. At SF-Foundry, we have seen firsthand how mastering this technology unlocks new levels of performance, allowing us to meet the most demanding specifications of our clients in automotive, aerospace, and high-tech industries.

Investing in and optimizing your automatic pouring process is an investment in the very future of your foundry. It builds a foundation of reliability that fosters trust, drives innovation, and secures a competitive edge in a demanding global market.

SF-Foundry: Engineering Precision, Casting the Future.

Interested in learning how advanced pouring automation can transform your foundry’s capabilities? Contact the SF-Foundry team today for a consultation.