In the realm of metal casting and processing, the utilization of advanced filtration systems such as Silicon Carbide Foam Ceramic Filters has revolutionized the industry’s approach to purifying molten metals. These filters, crafted from high-quality silicon carbide materials, stand out for their exceptional thermal stability, corrosion resistance, and efficient particle capture capabilities.

The Essence of Silicon Carbide Foam Ceramic Filters for Metal Filtration

Material Composition: Silicon Carbide Foam Ceramic Filters, engineered from silicon carbide, exhibit superior resistance to high temperatures, making them ideal for operations reaching up to 1560°C. This attribute ensures their reliability and effectiveness in filtering impurities and solid particles from molten metal streams.

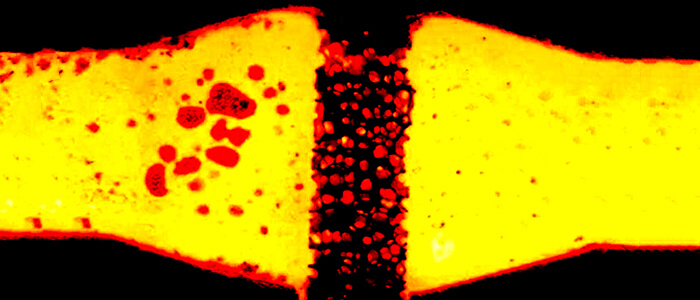

Porous Structure: The unique open-cell structure of these filters enables the efficient entrapment of contaminants, ensuring the purification and enhancement of metal quality during casting processes. The customizable pore sizes cater to a spectrum of filtration requirements, from fine particle removal to overall metal purity improvement.

Selecting Optimal Aperture and Dimensions

Application Specificity: Tailoring the aperture size and dimensions of the filters to the specific application is pivotal. Factors such as the type of metal being processed, particle size distribution, and flow rates must be considered to optimize filtration efficiency.

Efficiency vs. Flow Rate: Balancing the filter’s aperture size with the desired flow rate is crucial. Appropriate pore sizes prevent clogging while ensuring efficient particle capture and improved metal quality.

Customization and Industry Advantages

Customization Flexibility: Manufacturers offer a range of aperture sizes, shapes, and dimensions to meet diverse industrial needs. Customization ensures that the filter aligns precisely with the operational requirements of the metal processing facility.

Industry Applications: Silicon Carbide Foam Ceramic Filters find widespread application in foundries, metalworking, and other industries where the removal of impurities and enhancement of metal purity are paramount. Their ability to withstand extreme temperatures and harsh conditions makes them indispensable tools in metal casting processes.

In conclusion, Silicon Carbide Foam Ceramic Filters represent a pinnacle of innovation in metal filtration technology, offering unparalleled efficiency and reliability in ensuring the quality and purity of molten metals. By understanding the critical factors influencing aperture selection and dimensions, industry professionals can harness the full potential of these advanced filtration solutions for optimized metal processing outcomes.