When it comes to achieving high-quality metal casts, one crucial factor is controlling impurities and ensuring a smooth flow of molten metal. This is where the remarkable Silicon Carbide Ceramic Foam Filters come into play. Let’s explore the key advantages and benefits of this exceptional product.

Features of Silicon Carbide Ceramic Foam Filters:

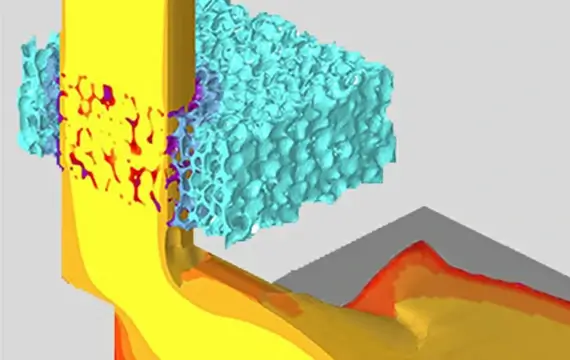

Unparalleled Porosity: The Silicon Carbide Foam Filter stands out with its exceptional porosity. Its intricate cellular structure creates a vast network of interconnected pores, acting as gatekeepers to trap impurities during the casting process. This precisely engineered porosity enables efficient filtration, effectively removing harmful contaminants like oxides, slag, and non-metallic inclusions.

Enhanced Filtration Efficiency: Our Silicon Carbide Ceramic Foam Filters boast a unique design that achieves unmatched filtration efficiency. The interconnected pores create multiple pathways for the molten metal to flow while effectively capturing impurities. This results in cleaner and purer metal casts, significantly reducing defects and improving overall casting quality.

Optimal Flow Control: To achieve defect-free casts, it is crucial to ensure a controlled and uniform flow of molten metal. The Silicon Carbide Ceramic Foam Filter excels in this aspect by facilitating smooth and regulated metal flow. Its porous structure strikes an ideal balance between permeability and flow resistance, minimizing turbulence and preventing the formation of undesirable defects like porosity or shrinkage.

Thermal Stability: Operating in high-temperature environments poses a common challenge in metal casting. Our Silicon Carbide Filters demonstrate exceptional thermal stability, maintaining their structural integrity even under extreme temperature differentials. This guarantees consistent and reliable filtration performance throughout the casting process, ensuring superior results.

Versatility and Compatibility: We understand that different casting processes require tailored solutions. That’s why our Silicon Carbide Ceramic Foam Filters are available in various shapes, sizes, and configurations to suit different casting techniques, including investment casting and sand casting. This versatility allows for seamless integration into your existing setup, enhancing the efficiency and effectiveness of your casting operations.

Inclusion:

By harnessing the power of porosity, SEFU’s Silicon Carbide Ceramic Foam Filters deliver outstanding filtration efficiency, precise flow control, and exceptional thermal stability. These characteristics result in higher-quality metal casts with reduced defects, leading to improved productivity and cost savings for your business.

Take your casting processes to new heights of excellence with SEFU’s Silicon Carbide Ceramic Foam Filters. Contact us today to discover how our innovative solutions can transform your metal casting operations and unlock the true potential of your products.