As a professional casting material manufacturer, SF-Foundry is committed to providing high-performance gating system solutions to global customers, helping foundries optimize metal liquid flow, reduce impurity defects, and improve casting yield.

The core role of the gating system

The gating system is the key channel for the metal liquid to enter the cavity from the ladle during the casting process, and its design directly affects the quality and production efficiency of the casting.

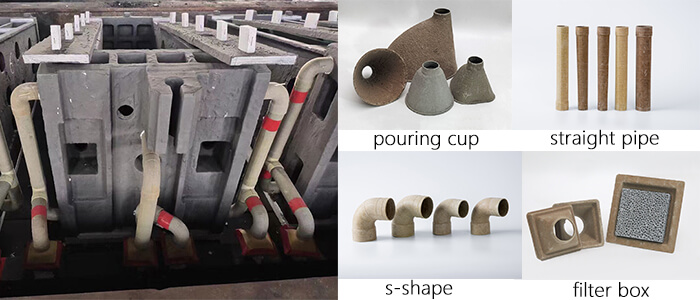

SF-Foundry’s paper casting runner is a replacement for the traditional ceramic runner. It is lightweight, heat-insulating and environmentally friendly. SF-Foundry’s foam ceramic filter can be integrated in the pouring cup, cross runner or straight runner of the paper runner system to efficiently intercept inclusions (such as oxides and slag) in the melt, ensure the purity of the metal liquid, and reduce defects such as pores and slag inclusions.

At the same time, our exothermic riser sleeve can further optimize the metal liquid shrinkage feeding effect, forming a complete pouring-filtration-shrinkage integrated solution.

Advantages of SF-Foundry’s paper pouring system

Lightweight design, reducing turbulence of molten metal

Biodegradable, environmentally friendly and easy to clean

Industry applications

SF-Foundry’s pouring system has been successfully used in automotive parts, engineering machinery, pump and valve castings and other fields.

About SF-Foundry

SF-Foundry is a manufacturer specializing in casting filter materials and pouring system components, with advanced production technology and strict quality control system. Our products serve the global foundry industry and are committed to providing customers with efficient and reliable molten metal purification and pouring optimization solutions. Our products cover key components such as foam ceramic filters, paper runners, and risers, which can fully adapt to the casting needs of various molten metals such as molten iron, molten aluminum, molten steel, and molten copper.

Foam ceramic filter

High temperature resistance (up to 1600℃), suitable for high melting point metals such as molten iron and steel

Optional aperture (10-50PPI), suitable for different casting precision requirements

High performance riser sleeve

Optimize shrinkage feeding efficiency, reduce shrinkage holes and shrinkage defects

Suitable for sequential solidification control of complex castings

Significantly reduce casting scrap rate and improve machining performance

For more technical details or samples, please visit our official website [www.sf-foundry.com] or contact our sales team.

Email: info@sf-foundry.com

WhatsApp: +8613785803358