What Are Sand Inclusions?

Sand inclusions are among the most common and frustrating defects found in metal castings, particularly in sand casting processes. At SF-Foundry, we’ve seen firsthand how these defects compromise the structural integrity, surface finish, and pressure tightness of cast components, leading to increased scrap rates, costly rework, and delayed deliveries.

A sand inclusion is exactly what it sounds like: a particle or cluster of moulding sand that becomes entrapped within the solidifying metal. They appear as irregular, rough pockets on the casting surface or just beneath it, often having a different colour and texture from the surrounding metal. These are not mere cosmetic flaws; they act as stress concentrators, severely weakening the part and often causing catastrophic failure in service.

The key to defeating this defect lies in a fundamental understanding: a filter is a critical tool, but it is never a substitute for proper sand practice. As we’ll explore, the battle against sand inclusions is fought on two fronts—mould quality and metal cleanliness—and requires a holistic approach.

Where Does the Sand Come From?

Sand inclusions originate from the disintegration of the mould or core itself. Through our experience working with foundries worldwide, we classify the primary causes into a few critical failure points:

Weak or Friable Mould Surfaces

This is a primary culprit. When the mould surface lacks sufficient strength, it can crumble under the thermal and mechanical assault of the molten metal.

-

Inadequate Binder: Incorrect binder type, ratio, or mixing leads to poor sand cohesion.

-

High Clay or Moisture Content: Creates a brittle surface that is prone to spalling.

-

Poor Compaction: Uneven or insufficient ramping leaves weak spots that easily erode.

Turbulent Metal Flow

The velocity and pattern of the metal as it fills the cavity is decisive. Turbulent flow acts like a sandblaster, scouring the mould walls and dislodging sand particles.

-

Poor Gating System Design: Systems that create a chaotic, splashing entry of metal into the cavity are a major source of sand wash.

-

Excessive Pouring Height: A high drop creates high velocity and impact, increasing erosion force.

Sand Erosion in the Running System

Before metal even reaches the cavity, it travels through gates and runners. If these passages are not properly consolidated, they erode first, sending a wave of loose sand ahead into the casting.

The Two-Front War: A Strategic Approach to Prevention

Defeating sand inclusions requires a dual-strategy system. One cannot succeed without the other.

Front 1: Building a Perfect, Robust Mould

The first and most critical line of defense is creating a mould that can withstand the casting process.

-

Optimise Sand Composition & Binding: This is foundational. Ensuring the correct grain size distribution, binder type (resin, clay), and additive levels is crucial. For green sand moulds, controlling moisture and active clay content is paramount. Corrective additives like dextrin are often the unsung heroes—they effectively reduce friability by improving the plasticity and cohesion of the sand mixture, creating a tougher, more resilient surface that is far less likely to break away.

-

Apply a Protective Barrier: A high-quality mould or core coating is indispensable. This refractory wash forms a tough, sintered layer on the sand surface, shielding it from direct metal contact and thermal shock.

-

Ensure Uniform, High-Density Compaction: Whether by hand ramming, jolting, or using modern automated systems, consistent and adequate compaction throughout the mould is non-negotiable for achieving uniform strength.

Front 2: Controlling and Cleaning the Metal Flow

Even with a perfect mould, controlling the metal’s journey is essential to capture any sand that does become dislodged.

-

Design for Laminar Flow: The goal is to fill the cavity smoothly and quietly. This involves using choke gates, tapered sprues, and runner extensions that reduce velocity and prevent direct impingement on mould walls.

-

Deploy Strategic Filtration: This is where SF-Foundry’s expertise directly delivers value. While a filter cannot cure poor mould quality, it is the ultimate safety net for capturing loose sand that has been carried into the flowing metal.

The Role of Filtration: Your Final, Critical Safety Net

It’s vital to understand what a filter can and cannot do, as outlined in the principle you shared. A filter placed in the gating system acts as a physical sieve. It is exceptionally effective at trapping loose sand, slag, and dross that are already suspended in the metal stream as it passes through the running system.

How Our Filters Work:

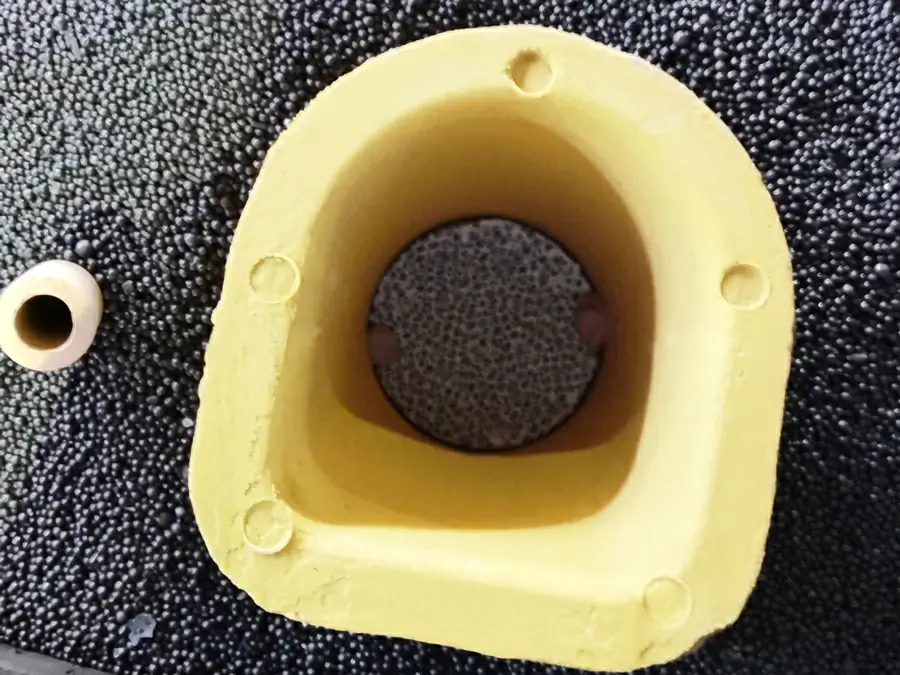

Our Ceramic Foam Filters (CFF) and Cellular/Cordierite Filters operate on deep-bed filtration principles. The metal stream is divided into hundreds of tiny channels as it passes through the intricate, three-dimensional network of the filter.

-

Mechanical Sieving: Larger sand particles are captured at the filter’s inlet face.

-

Deep-Bed Capture: Finer particles are adsorbed onto the internal ceramic walls of the filter’s cells as the metal navigates the tortuous path.

The Critical Limitation:

As the principle correctly states, sand that is already lying loose within the mould cavity itself, downstream of the filter, cannot be captured. This is why mould quality is the first and most important battle. The filter is your guardian of the metal stream, not a fix for a poor mould cavity.

For the metal stream, we supply the optimal filter. For heavy sand loads, a robust Cellular Filter with high mechanical strength is often ideal. For finer filtration, our Ceramic Foam Filters in the appropriate pore size (e.g., 10 ppi for coarse sand, 20 ppi for finer particles) provide exceptional capture efficiency.

Conclusion: A Partnership for Quality

Eliminating sand inclusions is a systematic exercise in process control. It requires excellence in mould-making practice paired with intelligent metal flow management and filtration.

Is sand inclusion rejection costing you productivity and profit? Partner with SF-Foundry. We bring more than just premium filters; we bring a deep understanding of the entire casting process. Let us help you analyse your defect patterns, strengthen your moulding practice, and implement the right filtration strategy to achieve consistently clean, high-quality castings.