Mexico is known for its rich industrial diversity, and amongst them is the foundry industry. With a history of metalworking that dates back to the Aztecs, it’s no surprise that Mexico has been producing casting products for centuries. The Mexican foundry industry is growing rapidly and has been forecasted to reach USD 4.5 billion by the year 2026. In this article, we will delve into the development of the Mexican foundry industry and its market analysis, along with the application of ceramic casting filter in Mexican foundries.

Development of the Mexican Foundry Industry

The Mexico foundry industry has come a long way since its humble beginnings. The earliest foundries in Mexico were used in the production of bells, statues, and architectural components. As the industry began to grow, so did the production of diverse products, including parts for automotive, aerospace, and transportation industries.

According to the National Chamber of Foundry and Ironworks (CANAFER), Mexico’s foundry industry produces over 2 million tons of metal casting per year. The industry is an important one, not only for Mexico but also for the world. In 2020, Mexican exports of cast iron and cast steel amounted to USD 1.3 billion, with the United States being its primary export destination. The industry’s success is attributed to the country’s strategic location, low labor costs, and high demand from local and international markets.

Market Analysis of the Mexican Foundry Industry

The Mexican foundry industry serves a wide range of markets, including transportation, construction, aerospace, mining, agriculture, and energy. According to a market research report by Global Market Insights, the transportation segment is the leading consumer of foundry products and represents 44% of the industry’s total volume share. The Mexico automotive industry is the largest manufacturing sector in the country and is projected to experience significant growth in the coming years. In fact, Mexican light-vehicle production is expected to surpass 5 million units annually by 2024.

The construction industry is another significant end-user of foundry products. With the growing demand for urbanization and infrastructure projects in Mexico, there is an increasing need for high-quality metal casting products. The aerospace industry is also a major consumer of foundry products, accounting for 5.6% of Mexico’s total metal casting volume. The industry has experienced significant growth in recent years, with Mexico being home to over 300 aerospace companies, including industry giants like Safran and Bombardier.

Application of Ceramic Casting Filter in Mexican Foundries

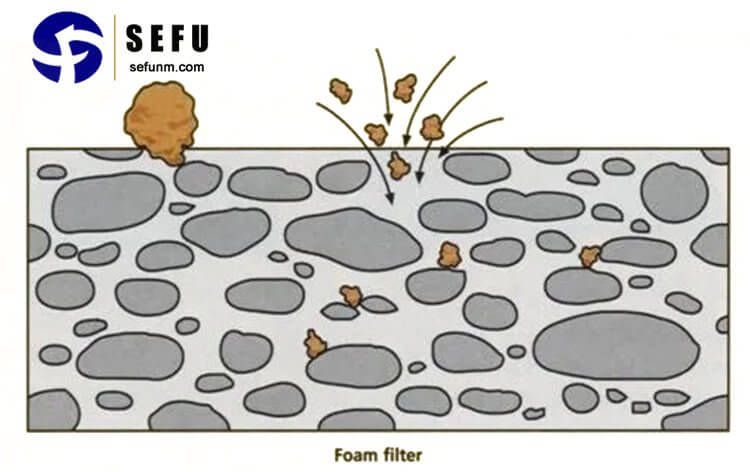

To ensure high-quality castings, foundries must implement proper filtration techniques that remove impurities from the molten metal. Ceramic casting filters are a critical component in foundry filtration systems, designed to remove impurities and increase the casting quality. Traditionally, foundries have used sand and zircon filters for casting filtration. However, these filters have limitations that can compromise the casting’s integrity.

Ceramic casting filters offer many advantages over traditional filters. They are made of high-purity ceramic materials that provide excellent thermal shock resistance, chemical resistance, and high-temperature performance. The filters’ open-cell structure enables them to remove impurities more effectively while allowing for steadier metal flow and reduced turbulence.

The use of ceramic casting filters in Mexican foundries is growing, with many foundries recognizing their benefits. The filters have found widespread use in the automotive, aerospace, energy, and other industries that require high-quality castings. Some of the notable foundries using ceramic casting filters in Mexico include Grupo Fiat Chrysler Automobiles, Aleaciones Estampadas, and Grupo Industrial de Fundiciones.

Conclusion

The Mexican foundry industry is experiencing rapid growth, thanks to its strategic location, low labor costs, and high demand from local and international markets. The industry serves a diverse range of markets, including transportation, construction, aerospace, mining, agriculture, and energy. The application of ceramic casting filters is becoming more widespread in Mexican foundries, enabling them to produce high-quality castings that meet the stringent demands of their customers. The future of the Mexican foundry industry looks bright, and with continued investment and innovation, it is poised to become a global leader in the metalworking industry.