In the intricate world of metal casting, where precision and quality are paramount, riser sleeves (also known as feeders) play a pivotal role in ensuring flawless castings. Beyond risers in metal casting mere presence, these components serve three fundamental functions that are indispensable in the realm of steel and iron casting.

What are the Three Main Functions of Riser?

1. Feeding: Nurturing the Casting Process

At the core of its purpose, a riser acts as a feeding source for the casting. As molten metal cools and solidifies, it undergoes shrinkage, which, if left unattended, can lead to defects within the casting. The riser acts as a reservoir of molten metal, supplementing the shrinkage and maintaining the integrity of the casting structure.

2. Heat Dissipation: Regulating the Casting’s Temperature

Beyond feeding, risers aid in heat dissipation, a crucial aspect in controlling the cooling rate of the metal. By absorbing excess heat, risers ensure uniform solidification throughout the casting, mitigating the risks of premature solidification and related defects.

3. Gas Removal: Enhancing Casting Purity

Another vital function of risers is gas removal. As the molten metal solidifies within the riser, any trapped gases tend to migrate towards the riser’s top, allowing for their escape. This process helps in reducing the presence of gas-related defects in the final casting, ensuring its purity and structural soundness.

Features of Risers in Metal Casting: Precision and Versatility

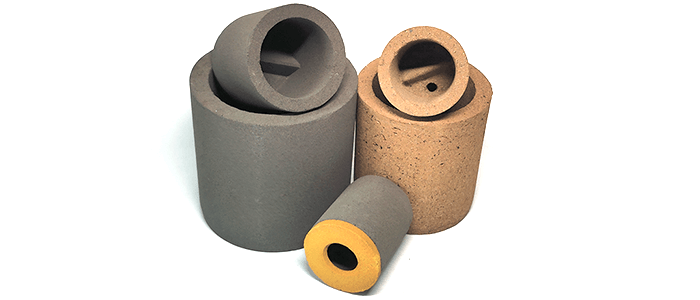

Risers come in various shapes and sizes, tailored to specific casting requirements. Their design often involves considerations such as material composition, insulating properties, and compatibility with different casting processes. Whether as open risers, blind risers, or exothermic risers, each variant is crafted to deliver optimal performance in diverse casting scenarios.

Applications in the Steel and Iron Industry: Enhancing Casting Quality

In the steel and iron industry, risers find extensive applications across a spectrum of casting processes. From steel foundries to iron casting facilities, risers are indispensable in achieving defect-free castings, improving yield rates, and enhancing the overall quality of the final products. Their role in ensuring consistent feeding, controlling solidification, and expelling gases makes them a cornerstone of efficient casting operations.

In conclusion, risers stand as silent guardians of casting perfection, embodying precision, functionality, and reliability. Their three main functions—feeding, heat dissipation, and gas removal—underscore their significance in the intricate art of metal casting, making them indispensable components in the pursuit of flawless castings.