Enhance Metal Casting Efficiency with Porous Silicon Carbide Ceramic Foam Filters

As a silicon carbide ceramic foam filter manufacturer, SF-Foundry is designed to optimize metal casting processes. Our porous silicon carbide filters are meticulously engineered to meet the demanding requirements of foundries and metalworking industries worldwide.

Material Composition: Our porous silicon carbide ceramic foam filters are crafted from high-quality silicon carbide material known for their exceptional thermal stability, mechanical strength, and chemical resistance.

Pore Structure: The filters feature a precisely engineered three-dimensional network of interconnected pores, enabling efficient filtration of impurities from molten metals during casting processes.

Operating Temperature: With a working temperature of up to 1500°C, our filters ensure reliable performance even in high-temperature casting applications.

Features of Porous Silicon Carbide Ceramic Foam Filters

Efficient Filtration: The porous structure of our silicon carbide ceramic foam filters effectively captures impurities such as oxides, slag, and non-metallic inclusions, ensuring cleaner metal flow and superior casting quality.

Thermal Stability: Designed to withstand extreme temperatures, our filters exhibit excellent thermal stability and resistance to thermal shock, ensuring prolonged usage in demanding foundry environments.

Customization Options: We offer a range of customization options including pore size, shape, and dimensions to suit specific casting requirements and production processes.

Applications of Porous Silicon Carbide Filters

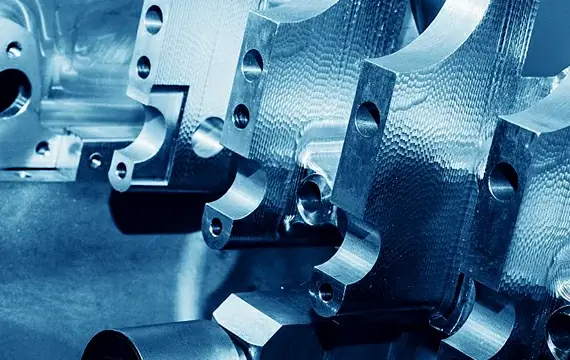

Automotive Industry: Our silicon carbide ceramic foam filters are widely used in automotive component manufacturing for casting engine blocks, cylinder heads, intake manifolds, and other critical parts.

Aerospace and Defense: Aerospace and defense industries rely on our filters for casting components with stringent quality and performance standards, including turbine blades, structural components, and aircraft parts.

General Metal Casting: Our filters find applications in a variety of metal casting processes for aluminum, iron, steel, copper, and other alloys across diverse industries.

Benefits of Porous Silicon Carbide

Improved Casting Quality: By removing impurities from molten metals, our filters help reduce defects such as porosity, shrinkage, and surface irregularities, resulting in superior casting quality.

Enhanced Productivity: With optimized metal flow and reduced rework, our filters contribute to increased productivity, shorter production cycles, and cost savings for foundries and manufacturers.

Compliance and Certification: Our products meet ISO 9001: 2015 quality standards and are certified for use in critical applications, ensuring compliance with regulatory requirements and customer specifications.

Related Product

Experience the difference in metal casting efficiency with our premium-quality porous silicon carbide ceramic foam filters. Contact us today to learn more about our products, customization options, and solutions tailored to your specific casting needs.

Contact Information:

- Tel/WhatsApp: +86 13785803358

- Email: info@sf-foundry.com