How do we achieve cleaner air, purer water, and improved industrial processes? The answer lies in porous ceramic filters. These remarkable filters have become indispensable in various fields due to their ability to efficiently separate contaminants from fluids. However, behind their effectiveness lies a complex manufacturing process. In this article, we will delve into the world of porous ceramic filters, exploring their manufacturing process in detail and uncovering the key steps and techniques involved.

Porous Ceramic Filters: Unraveling the Manufacturing Process

1. The Significance of Porous Ceramic Filters:

Before delving into the manufacturing process, it is essential to understand why porous ceramic filters hold such significance. These filters offer a unique combination of properties that make them ideal for numerous applications. They exhibit excellent thermal stability, corrosion resistance, high porosity, and precise pore size control. Additionally, they can withstand extreme temperatures and harsh chemicals, making them ideal for demanding environments. From environmental protection and water treatment to metal casting and pharmaceutical manufacturing, porous ceramic filters play a pivotal role in ensuring efficiency and quality across various industries.

2. Raw Materials Selection:

The first step in manufacturing porous ceramic filters is selecting the appropriate raw materials. Typically, these filters are made from a mixture of ceramic powders, binders, and pore-forming agents. The choice of ceramic powder depends on the desired properties of the filter, such as chemical resistance, porosity, and strength. Common ceramics used include alumina, zirconia, silicon carbide, and titania. The binders help in holding the mixture together during processing, while the pore-forming agents create the desired pore structure.

3. Mixing and Forming:

Once the raw materials are selected, they undergo a mixing process to achieve a homogenous blend. The mixture is often prepared in a ball mill or a similar device to ensure thorough blending. Subsequently, the mixed powder is shaped into the desired filter form using various techniques such as extrusion, pressing, or slip casting. Extrusion is commonly employed for producing cylindrical filters, while pressing is suitable for manufacturing flat filters. Slip casting, on the other hand, is utilized for complex filter shapes.

4. Drying and Pre-Sintering:

After forming, the filters undergo a drying process to remove excess moisture. This step is crucial to prevent cracks or defects during subsequent processing stages. The drying process can be achieved through natural evaporation or through the use of controlled temperature and humidity conditions. Once dry, the filters are subjected to pre-sintering, also known as the “bisque firing” process. Pre-sintering helps to strengthen the filters and facilitate the removal of binders and pore-forming agents.

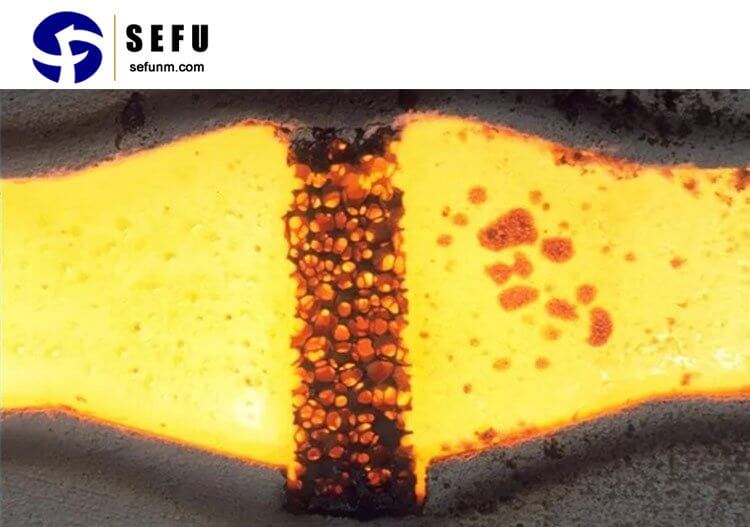

5. Sintering:

Sintering is the key step in the manufacturing process that imparts the final desired properties to the porous ceramic filters. The filters are heated at high temperatures, typically above the melting point of the ceramic particles but below their decomposition temperature. This causes the ceramic particles to bond together, resulting in a rigid, interconnected structure with well-defined pores. The sintering temperature and duration are carefully controlled to achieve the desired pore size, porosity, and strength.

6. Post-Processing and Finishing:

After sintering, the filters undergo post-processing steps to enhance their performance and functionality. This can include surface treatments to modify the filter’s surface chemistry, such as impregnation with catalysts or functional coatings. Additionally, finishing operations, such as machining or grinding, may be performed to achieve the desired dimensions and surface smoothness. Quality control measures are also implemented during this stage to ensure that the filters meet the required specifications.

7. Testing and Quality Assurance:

Once the filters are manufactured, they undergo rigorous testing to ensure their effectiveness and quality. This involves various characterization techniques, including pore size distribution analysis,