Aluminum casting is a crucial process in the manufacturing industry, especially in the production of automotive components, aerospace parts, and machinery components. The casting process involves pouring molten aluminum into molds or dies to shape the final product. However, the purity and quality of the aluminum can be compromised due to the presence of impurities, gases, and other contaminants. Therefore, purification methods such as filtration are necessary to eliminate these impurities, improve the casting quality, and reduce defects. Two common types of filters used in aluminum casting are Porous Ceramic Filters and Aluminum Ceramic Foam Filters. In this article, we will examine the key differences between these two filters and the dimensions of Porous Aluminum Ceramic Filters.

Porous Ceramic Filter for Aluminum Casting Purification

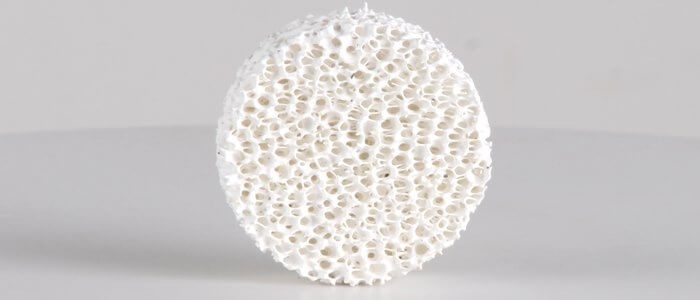

Porous Ceramic Filters (PCF) are widely used in the aluminum casting industry due to their efficiency in removing impurities, gas, and other contaminants from the molten aluminum. The PCF consists of a porous structure that allows the molten aluminum to pass through while retaining the impurities. The filter medium can vary in size, shape, and material composition depending on the specific application.

The PCF has several advantages over other filtration methods, including high efficiency, improved casting quality, reduced scrap, and extended furnace life. The filter also eliminates the need for degassing equipment, which often consumes a significant amount of time and energy.

One critical aspect that distinguishes the PCF from other filters is the material composition. The PCF is made of refractory ceramics with high thermal stability and chemical resistance. The ceramics can withstand the high temperatures and harsh chemical environments during the casting process without breaking down or degrading. The refractory material also promotes good wettability and adhesion to the molten aluminum, allowing for uniform filtration and reduced turbulence.

Aluminum Ceramic Foam Filter

The Aluminum Ceramic Foam Filter (ACFF) is another common type of filter used in the aluminum casting process. The filter has a three-dimensional structure consisting of interconnected pores. The pores can be either open or closed depending on the specific application and filtering requirements.

The ACFF has several advantages, including high filtration efficiency, good thermal shock resistance, and high-pressure resistance. The filter can remove impurities such as oxides, inclusions, and gas bubbles to improve casting quality and reduce defects. The filter also has a high thermal conductivity, which allows for rapid heating and cooling of the molten aluminum, reducing the casting cycle time.

The ACFF’s primary material composition is alumina, which is a refractory material with excellent thermal and chemical stability. The material can withstand extreme temperatures and chemical reactions during the casting process without degrading or causing contamination.

Key Differences between PCF and ACFF

The PCF and ACFF have several similarities, including high filtration efficiency and refractory material composition. However, there are also key differences between these two filters that must be considered when choosing a particular filter for a specific application. Some of the main differences are highlighted below.

1. Pore Structure

The PCF has a pore structure that is predominantly uni-directional, allowing for efficient filtration of impurities in a particular direction. The filter’s uni-directional nature also reduces turbulence and improves the filter’s longevity. On the other hand, the ACFF has a three-dimensional interconnected pore structure that allows for filtration in all directions. The filter’s open cell foam structure also promotes the adsorption of impurities, improving the filtration efficiency.

2. Filtration Efficiency

Both types of filters have a high filtration efficiency, but the ACFF typically has a higher filtration efficiency than the PCF due to its pore structure and material composition. The ACFF can remove smaller impurities such as inclusions and gas bubbles, which cannot be removed by the PCF.

3. Application

The PCF is primarily used for low-pressure aluminum casting applications with a low filtration requirement, such as sand casting, gravity casting, and permanent mold casting. The filter can also be used for high-pressure die casting with secondary filtration. The ACFF is commonly used for high-pressure die casting and other high-pressure applications that require a high filtration efficiency.

Dimensions of Porous Aluminum Ceramic Filter

The Porous Aluminum Ceramic Filter (PACF) is a type of PCF that is specifically designed for the aluminum casting industry. The filter has a porous structure that allows for efficient filtration of impurities, gases, and other contaminants from the molten aluminum. The PACF also has high thermal stability and chemical resistance, allowing it to withstand the harsh conditions of the casting process.

The PACF’s dimensions can vary depending on the specific filtration requirements and application. The filter is available in different shapes, sizes, and pore sizes to meet the specific needs of each casting process. Some of the common dimensions of the PACF are:

1. Rectangular Shape: 70 x 70 x 12 mm, 75 x 50 x 13 mm, 110 x 110 x 12 mm, 150 x 150 x 13 mm, 200 x 100 x 10 mm, among others.

2. Square Shape: 50 x 50 x 10 mm, 60 x 60 x 10 mm, 70 x 70 x 10 mm, 90 x 90 x 10 mm, among others.

3. Round Shape: 20 x 50 x 10 mm, 25 x 50 x 10 mm, 30 x 30 x 10 mm, 40 x 10 mm, among others.

The PACF’s pore size can range from 5 to 30 microns, depending on the specific filtration requirements. The filter’s recommended flow rate is between 0.03 to 0.06 m/s, depending on the aluminum casting process, furnace capacity, and other factors.

Conclusion

In summary, filtration is a crucial process in the aluminum casting industry to ensure the purity and quality of the final product. The Porous Ceramic Filter and Aluminum Ceramic Foam Filter are two common types of filters used in the casting process. The PCF is ideal for low-pressure casting applications, while the ACFF is suitable for high-pressure casting applications. The filters have different pore structures, filtration efficiencies, and material composition, which must be considered when selecting a particular filter for a specific application. The Porous Aluminum Ceramic Filter (PACF) is a type of PCF specifically designed for the aluminum casting industry, with varying dimensions and pore sizes to meet the specific filtration requirements of each casting process.