Paper runner tube is an environmentally friendly casting material made of paper fiber as the main raw material, mainly used to replace traditional ceramic runner tubes. It is made by adding high-temperature resistant adhesives and reinforcing agents through a special process and high-pressure molding.

Paper runners were first developed by Japan and applied to the casting industry. In recent years, with the advancement of China’s environmental protection policies and the upgrading of casting technology, many Chinese companies have achieved large-scale production and promoted the standardized development of the industry.

Performance Advantages of Paper Runner Tubes

Compared with traditional ceramic runners, paper runners have the following significant advantages:

- Environmentally friendly and degradable: waste paper is recycled and reused, which reduces solid waste emissions and reduces the environmental protection treatment costs of foundries compared to ceramic runners.

- Excellent high temperature resistance: It can withstand high temperatures above 1500℃ and is suitable for the pouring of high-temperature molten metals such as cast iron and cast steel. It has good resistance to molten iron scouring and will not deform or break due to high temperature.

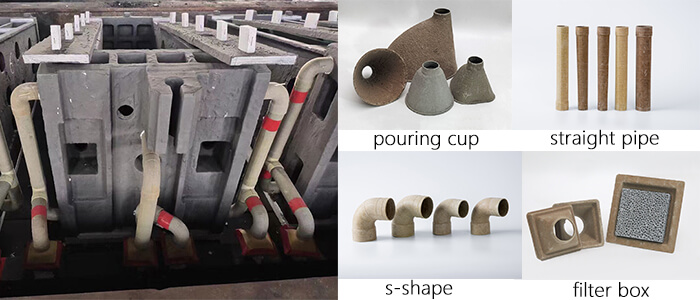

- Lightweight and easy to process: The weight is only 1/10 of that of a ceramic runner, making it easier to carry and install. It can be easily cut and drilled to meet the needs of different casting systems.

- Economical and efficient: High cost-effectiveness. Reduce metal waste during casting and improve the yield rate.

Application scenarios of paper runners

Paper runners are widely used in various iron casting processes such as gray cast iron and ductile iron, and are particularly suitable for the following scenarios:

Traditional sand casting

It performs well in resin sand casting and green sand casting, reducing defects such as pores and slag inclusions in castings.

Lost foam casting (EPC)

Lost foam casting requires extremely high stability of the casting system. The lightness and high temperature resistance of paper runners make them an ideal choice.

Precision casting

It is suitable for the casting of small and complex castings, reducing metal liquid turbulence and improving casting precision.

Future development trend of paper runner

As the foundry industry develops towards greening and intelligence, the application prospects of paper runner are broad:

Technological innovation: Research and develop higher strength and longer life paper-based composite materials to meet the needs of higher temperature alloy casting.

Market expansion: Promote from iron castings to more casting fields such as cast steel and aluminum alloys.

Conclusion

With its advantages of environmental protection, high temperature resistance, and economic efficiency, paper runners are gradually replacing traditional runner materials and becoming an ideal choice for iron casting production. In the future, with the advancement of technology and the expansion of the market, paper runners will play a more important role in the foundry industry and help enterprises achieve green transformation.