Introduction:

Molten aluminum casting is a widely utilized manufacturing process that transforms liquid aluminum into various shapes and forms, offering versatility and cost-effectiveness in the production of complex components. This article explores the molten aluminum casting process, its advantages, and diverse applications in industries such as automotive, aerospace, construction, and consumer goods.

I. Understanding Molten Aluminum Casting:

A. Overview of the Casting Process:

Melting: The process begins with the melting of aluminum scrap or ingots in a furnace, converting solid aluminum into a molten state.

Mold Preparation: A mold or die is used to shape the molten aluminum into the desired form. The mold can be made from various materials, such as steel, sand, or ceramic.

Pouring: The molten aluminum is poured into the prepared mold, filling the cavity and taking the shape of the mold.

Cooling: The molten aluminum solidifies as it cools, taking on the desired shape of the mold.

Ejection: Once the aluminum has solidified, the casting is removed from the mold, and any excess material is trimmed off.

B. Types of Molten Aluminum Casting:

Die Casting: In this process, the molten aluminum is injected at high pressure into a steel die, allowing for the rapid production of complex and precise components.

Sand Casting: A popular method for large and intricate parts, sand casting involves forming a mold from sand and pouring molten aluminum into the mold cavity.

Investment Casting: Also known as the lost-wax process, investment casting utilizes a wax pattern to create a mold that is later filled with molten aluminum.

II. Advantages of Molten Aluminum Casting:

A. Versatility and Complex Geometries:

Complex Components: Molten aluminum casting allows for the production of intricate and complex components with high dimensional accuracy.

Design Flexibility: The process accommodates a wide range of shapes, sizes, and part configurations, making it suitable for various applications.

B. Cost-Effectiveness:

Material Efficiency: Molten aluminum casting reduces material waste, as scrap aluminum can be recycled and reused in the casting process.

High Production Rates: The ability to produce a large number of components in a short time frame makes molten aluminum casting cost-effective for mass production.

C. Mechanical Properties:

High Strength-to-Weight Ratio: Aluminum castings offer excellent strength-to-weight ratios, making them desirable for lightweight and high-performance applications.

Good Machinability: Cast aluminum components can be easily machined to achieve precise tolerances and desired surface finishes.

D. Corrosion Resistance:

Inherent Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing excellent resistance to corrosion and rusting in various environments.

Weatherproofing: Aluminum castings are commonly used in outdoor applications, such as architectural fixtures and marine equipment, due to their ability to withstand harsh weather conditions.

III. Applications of Molten Aluminum Casting:

A. Automotive Industry:

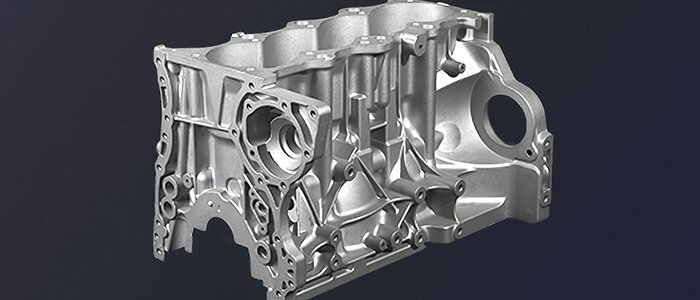

Engine Components: Molten aluminum casting is used to manufacture engine blocks, cylinder heads, pistons, and other critical engine components due to their lightweight, thermal conductivity, and high strength.

Transmission Housings: Cast aluminum components are employed in transmission housings, providing durability, reduced weight, and excellent heat dissipation.

B. Aerospace and Aviation:

Aircraft Components: Molten aluminum casting is utilized in the production of aircraft components, including wing structures, engine components, and landing gear parts, due to its lightweight and high structural integrity.

C. Construction and Architecture:

Building Components: Molten aluminum casting is used to create architectural components such as columns, balustrades, and ornamental fixtures, adding aesthetic appeal and durability to buildings.

D. Consumer Goods:

Household Appliances: The manufacturing of household appliances, such as cookware, pots, and pans, utilizes molten aluminum casting for its thermal conductivity, non-stick properties, and durability.

Electronics Enclosures: Aluminum castings are employed in the production of electronics enclosures, offering superior electromagnetic shielding and heat dissipation.

Here’s an example of “Aluminum Wheel Casting”:

One of the prime examples of molten aluminum casting is the production of aluminum wheels for vehicles. Aluminum wheels have gained popularity in the automotive industry due to their lightweight, corrosion resistance, and improved performance over traditional steel wheels.

The casting process for aluminum wheels typically involves the use of high-pressure die casting (HPDC) or low-pressure die casting (LPDC) methods. In HPDC, molten aluminum is injected into a steel die under high pressure, while LPDC utilizes a controlled atmosphere to pour the molten aluminum into a mold.

Advantages of Aluminum Wheel Casting:

- Lightweight: Aluminum wheels weigh significantly less than their steel counterparts, reducing the unsprung weight of the vehicle and improving fuel efficiency.

- Improved Performance: The reduced weight of aluminum wheels enhances vehicle handling, braking, and acceleration.

- Corrosion Resistance: Aluminum wheels are naturally corrosion-resistant, making them ideal for various weather conditions and road environments.

- Aesthetic Appeal: Aluminum wheels offer an attractive and modern appearance, enhancing the overall aesthetics of the vehicle.

- Heat Dissipation: Aluminum’s high thermal conductivity aids in dissipating heat generated during braking, reducing the risk of brake fade.

- Customization: The molten aluminum casting process allows for the production of wheels with intricate designs and custom finishes, catering to various vehicle styles and preferences.

IV. Advancements and Innovations in Molten Aluminum Casting:

A. Advanced Casting Techniques:

Semi-Solid Casting: Semi-solid casting, also known as thermoforming, involves processing aluminum in its semi-solid state, combining the advantages of both casting and forging techniques. This method enhances the mechanical properties of cast components, resulting in higher strength and improved ductility.

Vacuum Casting: Vacuum casting involves degassing the molten aluminum to remove impurities and gases, producing high-quality, defect-free components with improved mechanical properties and surface finish.

B. Alloy Development:

Aluminum Alloys: Ongoing research focuses on developing new aluminum alloy compositions with enhanced properties, tailoring alloys to specific applications, such as automotive lightweighting, aerospace, and high-temperature applications.

Nanostructured Alloys: Incorporating nanoparticles into aluminum alloys improves their mechanical properties and performance, leading to stronger, more durable cast components.

C. Computational Modeling and Simulation:

Process Optimization: Computational modeling, such as finite element analysis (FEA) and computational fluid dynamics (CFD), aids in optimizing casting processes, predicting casting defects, and improving component design.

Predictive Simulation: Advanced simulation tools enable the prediction of casting defects, porosity formation, and residual stress, allowing for improved casting quality and process control.

V. Environmental Considerations and Sustainability:

A. Recycling and Energy Efficiency:

Sustainable Sourcing: The recycling of aluminum scrap reduces the need for primary aluminum production, conserving energy and natural resources.

Energy-Efficient Melting: Advances in furnace technology and energy-efficient melting practices further reduce the environmental impact of molten aluminum casting.

B. Emission Reduction:

Emission Control Systems: Molten aluminum casting facilities implement emission control technologies to reduce air pollutants and greenhouse gas emissions, contributing to a cleaner and more sustainable process.

C. Waste Minimization:

Residual Material Recycling: By recycling waste materials from the casting process, such as ceramic molds and metal chips, the amount of waste sent to landfills is minimized, promoting sustainable waste management practices.

VI. Challenges and Future Outlook:

A. Material Efficiency and Waste Reduction:

Process Optimization: Further optimization of the molten aluminum casting process is required to minimize material waste and improve material efficiency.

Recycling Technologies: Advancements in recycling technologies for ceramic molds and other casting-related waste can enhance the sustainability of the process.

B. Environmental Impact:

Sustainable Manufacturing Practices: Continued efforts to implement sustainable manufacturing practices, such as renewable energy use and water conservation, will help reduce the environmental impact of molten aluminum casting.

Green Casting Technologies: Research and development of greener casting technologies, such as using green sand molds or water-based binders, can further enhance the sustainability of the process.

C. Advancements in Alloy Development:

High-Performance Alloys: Advancements in alloy development will lead to the creation of high-performance aluminum alloys tailored for specific applications, offering improved mechanical properties and corrosion resistance.

D. Integration of Digital Technologies:

Industry 4.0: The integration of digital technologies, such as IoT sensors and data analytics, into molten aluminum casting processes, will enable real-time monitoring, predictive maintenance, and enhanced process control.

Conclusion:

Molten aluminum casting remains a vital and versatile manufacturing process with a multitude of advantages that drive innovation across various industries. Its versatility, cost-effectiveness, and exceptional mechanical properties make it an ideal choice for producing complex components, such as automotive wheels and aircraft parts.

As technology and research continue to advance, the industry can expect to witness improvements in casting techniques, alloy development, and sustainability practices. Embracing environmentally responsible manufacturing practices, recycling efforts, and the integration of digital technologies will ensure that molten aluminum casting continues to be a sustainable and crucial process for meeting the demands of modern manufacturing and driving progress in diverse industrial applications.