Introduction:

Foundry ceramic filters play a vital role in the casting industry by ensuring the production of high-quality metal components. These filters act as a barrier between the molten metal and the casting mold, removing impurities and enhancing the overall integrity of the final product. One such widely used filter is the magnesium oxide filter, which possesses exceptional properties that make it highly effective in the casting process.

Description of Magnesium Oxide Filters:

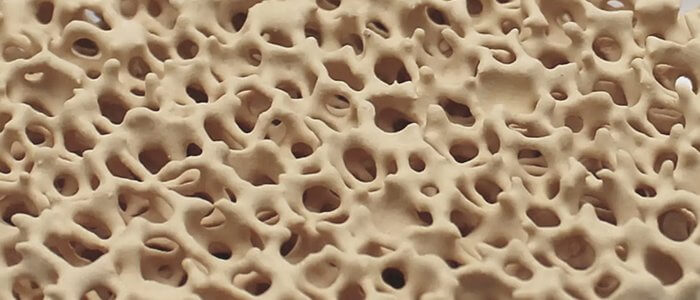

Magnesium oxide filters, also known as magnesia filters, are made from high-purity magnesium oxide refractory materials. These filters feature a porous structure with interconnected channels that facilitate the flow of molten metal while trapping impurities. The high thermal stability and chemical inertness of magnesium oxide allow it to withstand the extreme temperatures and corrosive environments encountered in metal casting.

The porosity of magnesium oxide filters is carefully controlled to achieve optimal filtration efficiency. The filter’s porous structure enables the removal of unwanted impurities such as non-metallic inclusions, slag, oxides, and sand particles, which can detrimentally affect the mechanical properties and surface finish of castings. By efficiently capturing these impurities, magnesium oxide filters contribute to the production of defect-free and high-integrity castings.

Application Field

Automotive Industry:

In the automotive industry, filters play a crucial role in casting components such as engine blocks, cylinder heads, and transmission housings. The presence of impurities in these critical components can lead to reduced performance, premature failure, or compromise safety. By employing magnesium oxide filters, manufacturers ensure that the molten metal used for casting is free from harmful contaminants, resulting in durable and reliable automotive parts.

Aerospace Sector:

The aerospace industry demands precision and uncompromised quality in its cast components, as they are subjected to extreme operating conditions. Filters, including magnesium oxide filters, are essential for producing turbine blades, aerospace structural parts, and landing gear components. By removing impurities, these filters contribute to the high strength, superior dimensional accuracy, and enhanced fatigue resistance of castings, ensuring safe and efficient performance in aerospace applications.

Medical Device Manufacturing:

The medical device industry requires the production of intricate cast components with stringent quality standards. Filters, including magnesium oxide filters, are employed in the manufacturing of implantable devices, orthopedic implants, and surgical instruments. By utilizing filters, manufacturers can eliminate impurities that may cause biocompatibility issues or compromise the structural integrity of medical devices, ensuring the safety and efficacy of these life-saving products.

Power Generation:

In the power generation sector, filters are indispensable for casting turbine blades, vanes, and other components used in gas and steam turbines. Magnesium oxide filters effectively remove contaminants such as sand, slag, and oxides from the molten metal, resulting in castings with excellent creep resistance, high-temperature stability, and improved operational efficiency. By ensuring the integrity of these critical components, filters contribute to the reliable and efficient operation of power plants.

Conclusion:

Foundry ceramic filters, particularly magnesium oxide filters, have proven to be essential in the casting process across various industries. These filters efficiently remove impurities from molten metal, ensuring the production of high-quality castings with enhanced mechanical properties and dimensional accuracy. Whether in the automotive, aerospace, medical, or power generation sectors, filters play a critical role in delivering defect-free components that meet the stringent requirements of modern manufacturing. The continuous advancement and utilization of effective filters like magnesium oxide filters are paramount to achieving excellence in the casting industry.