What is Lost-Foam Casting? Revolutionizing Shape Complexity

Lost-Foam Casting (LFC), also known as the evaporative pattern process, is a distinctive and innovative casting method that allows for the production of highly complex metal parts with exceptional design freedom. At its core, LFC uses a pattern made of expandable polystyrene (EPS) foam that is vaporized by molten metal, leaving a precise metal replica in its place. From our experience at SF-Foundry, this process bridges a unique gap between the simplicity of sand casting and the precision of investment casting, making it a compelling choice for specific applications in automotive, machinery, and pump industries.

Unlike traditional methods that require removing a rigid pattern from a sand mold, the foam pattern in LFC remains embedded. This fundamental difference eliminates parting lines and the need for cores in many designs, enabling internal passages, undercuts, and geometries that are otherwise impossible or prohibitively expensive to achieve.

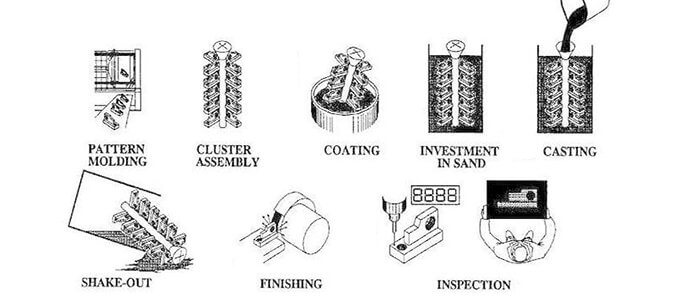

The Lost-Foam Casting Process: A Step-by-Step Breakdown

The LFC process is a sequence of carefully controlled steps where each stage is critical to the final quality of the casting.

1. Pattern & Cluster Production

-

A foam pattern—an exact replica of the desired part—is created by injecting expandable polystyrene beads into an aluminum die. For complex parts, multiple foam sections can be glued together seamlessly.

-

These patterns are then attached to a central foam gating system (sprue, runners, and ingates) to form a complete “cluster” or “tree.”

2. Coating the Cluster

-

The entire foam cluster is dipped into a proprietary refractory ceramic coating. This is a critical step we at SF-Foundry pay close attention to.

-

The coating serves multiple vital functions: it provides a smooth surface finish on the final casting, enhances the sand’s stability around the delicate foam, and controls the rate of foam gasification during pouring. The coating must be strong yet permeable enough to allow the foam decomposition gases to escape into the surrounding sand.

3. Sand Compaction

-

The coated cluster is placed in a flask and surrounded by unbonded, dry sand (typically silica). The sand is then compacted, usually through vibration, to fill all cavities and provide uniform, robust support around the pattern. The sand’s flowability is key here.

4. Pouring & Replication

-

Molten metal is poured directly into the top of the foam gating system. As the metal advances, the intense heat causes the foam to vaporize and decompose in a controlled front, with the metal exactly replacing the space the foam occupied—hence the name “evaporative pattern.”

-

The process requires controlled pouring speed and metal temperature to ensure the foam gases are vented through the coating and sand without causing turbulence or defects in the metal.

5. Cooling & Shakeout

-

After the metal solidifies, the flask is inverted, and the loose, unbonded sand flows away, freeing the metal cluster. The individual castings are then cut from the gating system and finished.

Key Advantages and Challenges of Lost-Foam Casting

Major Advantages:

-

Unmatched Design Freedom: No draft angles or parting lines are required. Complex internal geometries can be cast as single pieces, drastically reducing assembly needs.

-

Excellent Dimensional Accuracy: The process yields good as-cast tolerances and surface finish, minimizing machining.

-

Process Simplicity & Efficiency: Eliminates core-making, binders, and mold assembly. Sand is dry and 99% recyclable, making it an environmentally friendly option.

-

Reduced Machining & Weight: Allows for hollow sections and optimized designs, leading to lighter components and less material waste.

Key Challenges & Considerations:

-

Pattern Cost & Lead Time: The aluminum tooling for foam patterns can be expensive, making the process more economical for medium to high-volume runs (typically thousands of parts).

-

Process Sensitivity: The quality is highly dependent on foam density, coating properties, sand compaction, and pouring parameters. Inconsistent foam can lead to defects.

-

Defect Susceptibility: Unique defects like carbon defects (from incomplete foam vaporization) and fold defects (from poor foam collapse) can occur if the process is not meticulously controlled.

-

Material Limitations: Best suited for aluminum, iron, and steel. It is less common for very high-temperature alloys like nickel-based superalloys.

Lost-Foam vs. Other Casting Processes: When to Choose It

| Feature | Lost-Foam Casting (LFC) | Sand Casting | Investment Casting |

|---|---|---|---|

| Pattern/Mold | Expendable EPS foam pattern in unbonded sand. | Reusable pattern in bonded sand mold. | Expendable wax pattern in ceramic shell. |

| Design Complexity | Extremely High (internal features, no drafts). | Moderate (limited by pattern removal). | Extremely High (fine detail, thin walls). |

| Surface Finish | Good to Very Good. | Rough. | Excellent. |

| Dimensional Accuracy | Good. | Fair. | Very High. |

| Typical Volume | Medium to High (to amortize pattern tooling). | Low to High. | Low to Medium. |

| Setup Cost | High (aluminum foam die). | Low. | Medium-High (metal die for wax). |

| Best For | Complex geometry parts in high volume (engine blocks, cylinder heads, pump housings). | Large, simple parts in any volume. | High-precision, complex parts in lower volumes (aerospace, medical). |

The Verdict: Choose Lost-Foam Casting when you have a complex part design that would require multiple cores in sand casting, and you have production volumes high enough to justify the initial pattern tooling cost.

SF-Foundry’s Support for Optimized Lost-Foam Casting

While Lost-Foam is a distinct process, achieving high yields still depends on metal quality and pouring control. This is where SF-Foundry’s expertise adds critical value.

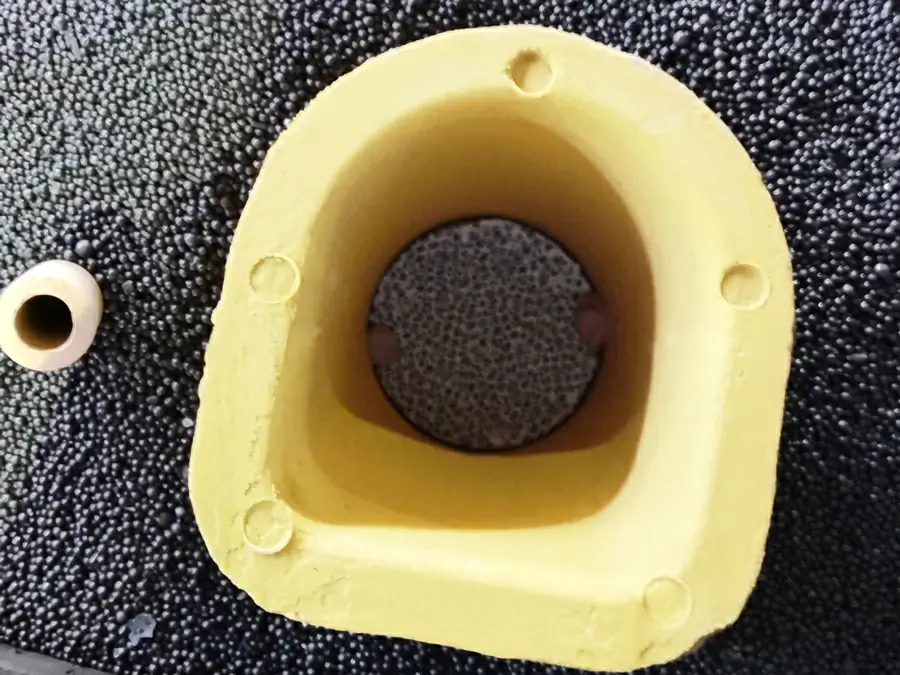

Ensuring Clean Metal for Flawless Filling: The metal must be exceptionally clean to flow smoothly and replicate the fine foam details without interruption. We recommend and supply Ceramic Foam Filters (CFF) to be used in the pouring basin or gating system of the LFC setup. This filters out oxides and inclusions that could cause surface defects or turbulence during the critical foam replacement phase.

Material & Process Insight: From our collaborations, we understand that the interaction between the metal, the decomposing foam, and the ceramic coating is delicate. We provide technical consultation on gating design and metal treatment best practices to complement the LFC process and minimize characteristic defects.

Conclusion: Is Lost-Foam Casting Right for Your Component?

Lost-Foam Casting is a powerful, niche process that unlocks new possibilities in metal component design. It excels at producing complex, near-net-shape parts in series production, offering significant savings in assembly and machining.

Considering Lost-Foam? Evaluate your part’s geometry complexity, required annual volume, and target cost. If the design benefits are clear and the volume justifies the tooling, LFC can be a highly competitive solution.

Partner with SF-Foundry to ensure the metal entering your Lost-Foam mold is of the highest possible quality. Contact us to discuss how our filtration and pouring solutions can be integrated into your LFC line to enhance yield, consistency, and final part performance.