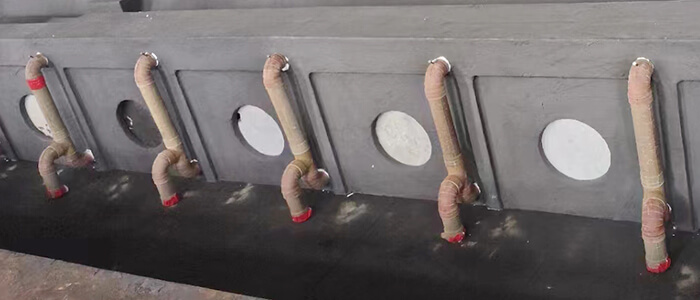

Recently, there has been a surge of interest in an innovative product – paper gating systems – within the casting sector. Crafted from refractory paper pulp and other durable refractory materials, these gating systems boast exceptional fire resistance properties, making them a preferred choice for the production of cast iron components, including applications in investment casting and traditional sand casting processes.

Manufacturing Materials:

The manufacturing materials of paper gating systems primarily include refractory paper pulp and other refractory materials. Through specialized processing and formulation, these materials endow gating systems with outstanding fire resistance and stability.

Fire Resistance Performance:

Paper gating systems exhibit remarkable fire resistance capabilities, capable of withstanding the high temperatures and pressures prevalent in casting environments. Operating seamlessly in conditions reaching 1640 degrees Celsius, these gating systems maintain stability, ensuring the smooth progression of casting processes.

Advantages Comparison:

When compared to traditional casting gating systems, paper gating systems present a host of advantages:

- Lightweight Design: Gating systems are lighter and more portable than traditional gating systems, reducing physical strain on operators.

- Environmental Sustainability: Crafted from recyclable materials, the gating systems are environmentally friendly, minimizing waste generation and aligning with sustainability objectives.

- Optimized Casting Effects: Engineered for enhanced casting processes, the gating systems improve casting quality, reduce waste, and boost operational efficiency.

- Fire Resistance and Stability: Constructed from high-quality refractory materials, paper gating systems exhibit superior fire resistance and stability, guaranteeing casting quality and production efficiency.

In conclusion, these innovative paper gating systems hold significant promise in the foundry industry. With their exceptional fire resistance, environmental sustainability, and operational convenience, they offer foundries a more efficient and sustainable solution, propelling the industry towards a smarter and greener future.