Introduction:

Foam ceramic filter has revolutionized the metal casting industry by providing efficient impurity removal and improved casting quality. In recent years, significant innovations have taken place in the design and manufacturing of ceramic foam filters, leading to enhanced filtration efficiency, increased versatility, and improved performance. This article explores the latest advancements in foam ceramic filter design and manufacturing, highlighting key innovations and their impact on the casting process.

Ⅰ. Importance of Foam Ceramic Filters in Metal Casting:

A. Filtration Efficiency:

Impurity Removal: Ceramic foam filters effectively remove impurities, such as oxides, inclusions, and slag, from the molten metal during casting.

Casting Quality: The removal of impurities results in higher casting quality, reduced defects, and improved mechanical properties in the final products.

B. Process Optimization:

Flow Control: Ceramic foam filters contribute to better metal flow control during casting, reducing turbulence and enabling the production of complex and intricate castings.

Mold Filling: The filters facilitate improved mold filling, ensuring complete cavity occupation and reducing the likelihood of misruns and cold shuts.

Ⅱ. Advances in Foam Ceramic Filter Design:

A. Material Innovations:

Enhanced Filtration Efficiency: Research focuses on developing advanced ceramic materials with improved filtration properties, such as higher porosity and tailored pore size distributions.

Customized Filters: Material modifications enable the customization of filters to specific casting requirements, optimizing filtration efficiency for different alloys and applications.

B. Geometric Configurations:

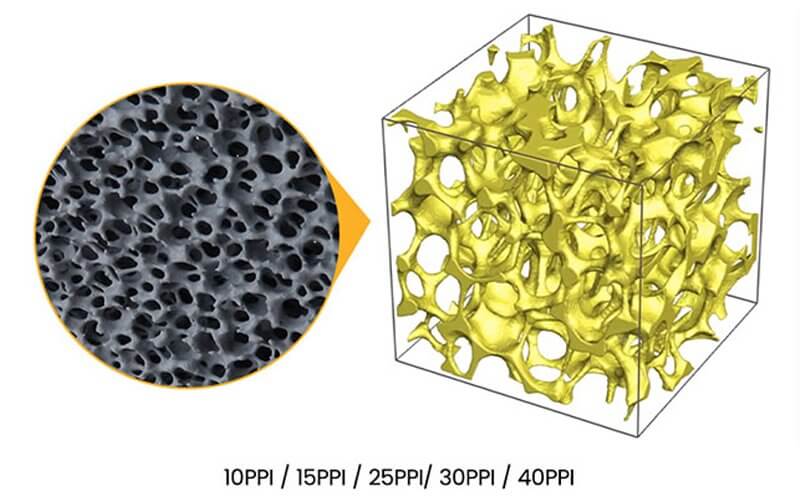

Three-Dimensional Structures: Innovations in filter design involve intricate three-dimensional lattice configurations, providing higher surface area for impurity capture and improving overall filtration efficiency.

Tailored Pore Size Distribution: Filters with specific pore size distributions are designed to target different impurities, allowing for more efficient removal based on the size and type of contaminants.

C. Composite Filters:

Functional Additives: Composite filters combine ceramic foam materials with functional additives, such as activated carbon or other catalytic materials, to enhance impurity capture and filtration efficiency.

Multi-Layered Filters: Composite filters with multiple layers of different materials offer improved impurity removal capabilities, enabling the filtration of a wider range of contaminants.

Ⅲ. Manufacturing Innovations:

A. Foam Preparation Techniques:

Polymeric Precursor Method: Innovations in the preparation of ceramic foam involve the use of polymeric precursors to create tailored foam structures with controlled cell sizes and distribution.

Template-Assisted Methods: Template-assisted techniques enable the fabrication of ceramic foams with well-defined shapes, sizes, and interconnected structures, enhancing overall filter performance.

B. Infiltration and Sintering Processes:

Enhanced Infiltration Methods: Improved infiltration techniques ensure the uniform impregnation of the foam structure, enhancing the integrity and performance of the foam ceramic filters.

Binder Removal and Sintering: Innovations in binder removal and sintering processes enhance the mechanical strength and thermal stability of the filters, improving their durability and resistance to high-temperature environments.

C. Additive Manufacturing:

3D Printing: Additive manufacturing techniques, such as 3D printing, enable the fabrication of complex filter designs with precise control over pore size, shape, and distribution.

Design Flexibility: Additive manufacturing allows for the creation of customized filters with intricate geometries, enabling optimized filtration performance for specific casting applications.

Ⅳ. Performance and Application Advancements:

A. Higher Filtration Efficiency:

Reduced Pore Blocking: Innovations in filter design and material composition help minimize pore blockage during the casting process, maintaining a high and consistent filtration efficiency.

Improved Impurity Capture: Advancements in filter design enable better impurity capture by optimizing the contact and interaction between impurities and the filter surface.

B. Versatility and Application Range:

Expanded Compatibility: Innovations in ceramic foam filter design and material selection enhance compatibility with a wider range of casting materials, including aluminum, steel, iron, and various alloys.

Customized Solutions: Filter design advancements allow for tailored solutions to meet the specific requirements of different casting processes and industries.

C. Advanced Casting Techniques:

Investment Casting: Ceramic foam filters have been successfully integrated into investment casting processes, enabling the production of high-precision castings with intricate details.

Continuous Casting: Innovations in foam ceramic filter design and manufacturing address the challenges of continuous casting processes, enhancing casting quality and reducing defects.

Ⅴ. Future Directions and Emerging Trends:

A. Nanotechnology and Advanced Materials:

Nanostructured Filters: Nanotechnology-based approaches offer the potential to create nanostructured ceramic foam filters with enhanced filtration efficiency and targeted impurity removal.

Hybrid Materials: Combining ceramic materials with nanoparticles or nanofibers enhances filter properties, such as mechanical strength, thermal stability, and filtration performance.

B. Digitalization and Process Optimization:

Modeling and Simulation: Advanced modeling techniques, such as computational fluid dynamics (CFD) simulations, aid in optimizing filter design, placement, and process parameters for improved casting quality.

Real-time Monitoring: Integration of sensors and real-time monitoring systems enables continuous process monitoring, ensuring optimal filter performance and facilitating proactive maintenance.

C. Sustainability and Environmental Considerations:

Green Manufacturing Practices: Research focuses on developing sustainable and eco-friendly manufacturing processes for ceramic foam filters, including the use of recyclable materials and energy-efficient techniques.

Waste Reduction and Recycling: Innovations aim to minimize waste generation during filter production and explore recycling methods for used filters, reducing environmental impact.

Ⅵ. Advancements in Quality Control and Testing:

A. Non-Destructive Testing:

X-ray Imaging: X-ray imaging techniques enable non-destructive inspection of ceramic foam filters, allowing for the detection of defects, such as cracks or voids, that may impact filter performance.

Porosity Measurement: Advanced imaging and analysis methods provide precise measurements of filter porosity, aiding in quality control and ensuring consistent filtration performance.

B. Mechanical Strength Assessment:

Mechanical Testing: Innovations in mechanical testing methods allow for the evaluation of filter strength, durability, and resistance to thermal and mechanical stress.

Finite Element Analysis (FEA): FEA simulations enable the prediction of mechanical behavior, stress distribution, and deformation of ceramic foam filters, guiding design improvements for enhanced structural integrity.

Ⅶ. Industry Collaboration and Knowledge Exchange:

A. Research Institutions and Universities:

Collaborative Research: Partnerships between research institutions, universities, and industry players foster knowledge exchange, enabling the exploration of new concepts, materials, and manufacturing techniques.

Technology Transfer: The transfer of research findings to industry helps bridge the gap between academia and practical applications, driving the adoption of innovative foam ceramic filter designs and manufacturing processes.

B. Industry Conferences and Trade Shows:

Technical Presentations: Industry conferences and trade shows provide platforms for experts to share their findings, advancements, and case studies related to foam ceramic filters, encouraging industry-wide knowledge dissemination.

Networking Opportunities: These events foster collaboration, allowing professionals from different sectors of the metal casting industry to connect, exchange ideas, and explore potential partnerships.

Ⅷ. Regulatory Compliance and Standards:

A. Quality Standards:

ISO Certification: Compliance with international standards, such as ISO 9001, ensures consistent quality control in ceramic foam filter manufacturing, guaranteeing reliable and high-performance products.

Industry-Specific Standards: Certain industries may have specific standards or certifications that govern the design and performance requirements of ceramic foam filters in their casting processes.

B. Environmental and Safety Regulations:

Material Selection: Compliance with regulations governing the use of certain materials, such as hazardous substances, ensures the safety and environmental sustainability of ceramic foam filter manufacturing.

Waste Management: Adherence to waste management regulations ensures proper disposal or recycling of used filters, minimizing environmental impact.

Ⅸ. Challenges and Future Directions:

A. Scalability:

Large-Scale Production: Overcoming challenges associated with the scalability of ceramic foam filter manufacturing is necessary to meet the growing demand of the metal casting industry.

Consistency and Uniformity: Ensuring consistent filter quality and performance across large-scale production is a key challenge that requires process optimization and advanced quality control measures.

B. Cost-Effectiveness:

Manufacturing Efficiency: Innovations should focus on optimizing manufacturing processes to reduce production costs while maintaining high-quality standards.

Material Selection: Exploring cost-effective yet high-performance materials for ceramic foam filter manufacturing contributes to overall cost reduction.

C. Advanced Materials and Additive Manufacturing:

Multifunctional Filters: Advancements in material science aim to develop foam ceramic filters with additional functionalities, such as improved chemical resistance or catalytic properties, enhancing their value and application range.

Additive Manufacturing Techniques: Further development of additive manufacturing processes for ceramic foam filters holds promise for rapid prototyping, customization, and cost-effective production.

Conclusion:

The continuous innovations in foam ceramic filter design and manufacturing have driven significant improvements in filtration efficiency, casting quality, and process optimization.

Material advancements, geometric configurations, and manufacturing techniques have contributed to enhanced impurity removal capabilities, increased versatility, and improved filter performance.

Quality control and testing methods ensure consistent filter quality, while industry collaboration and knowledge exchange foster advancements and the adoption of innovative designs and manufacturing processes.

Overcoming scalability and cost-effectiveness challenges, along with the exploration of advanced materials and additive manufacturing techniques, will further shape the future of ceramic foam filters in the metal casting industry.

With ongoing research and industry collaboration, ceramic foam filters will continue to play a vital role in achieving high-quality castings and driving innovation in metal casting processes.