India is a giant in the global castings market with vast expertise in producing a wide range of castings. The country ranks among the top ten countries for casting production globally, with an annual production of over 11.7 million tons. The Indian casting market has grown exponentially over the years due to the country’s technological advancements, a skilled workforce, and favorable government policies. In this article, we will delve into the analysis of the Indian casting market and the price of ceramic foam filters in India.

Overview of the Indian Casting Market

The Indian casting market is one of the key contributors to the country’s engineering industry. The Indian casting industry is highly diverse, producing a wide range of castings for various sectors such as automotive, construction, and defense. The industry is driven by a combination of factors such as increasing demand for lightweight and high-performance components, government support, and the availability of skilled labor.

Automotive Industry

The automotive industry is one of the major end-users of castings in India, accounting for over 39% of the total casting production. The growth in the Indian automotive industry has led to an increase in the demand for castings used in automobiles, such as engine blocks, cylinder heads, and transmission components. The castings used in the automotive industry require high precision, durability, and the ability to withstand high temperatures and pressure.

Construction Industry

The Indian construction industry is the second-largest end-user of casting components, accounting for over 18% of the total production. Castings used in the construction industry include valves, pumps, and pipes, which are integral components in building and construction.

Aerospace and Defense Industry

The Indian aerospace and defense industry is a growing segment of the casting industry. The industry is critical to the growth of the Indian economy, with the government investing in various initiatives to enhance domestic production capabilities. Castings used in the aerospace and defense industry require high precision, strength, and the ability to withstand extreme temperatures and pressures.

Challenges Faced by the Indian Casting Industry

The Indian casting industry faces several challenges that affect its growth potential, including:

1. High production costs due to the use of outdated technology and equipment.

2. Lack of skilled manpower, which affects the quality of castings and increases production costs.

3. Inconsistent demand from end-users, resulting in uneven production and inventory holding costs.

4. The high cost of raw materials, such as steel and iron, which account for a significant portion of the production costs.

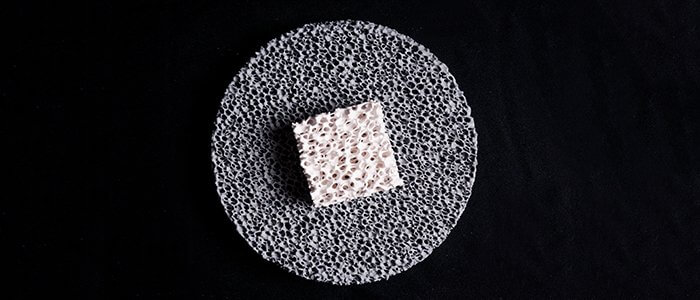

Price of Ceramic Foam Filter in India

Ceramic foam filters are used extensively in the casting industry to remove impurities from molten metal, producing high-quality final products. These filters enhance the product quality by filtering out impurities such as slag and oxides, which can affect the mechanical properties of the castings. The price of ceramic foam filters in India varies depending on the type of filter, its size, and the supplier.

The cost of a ceramic foam filter in India ranges from INR 200 to INR 800, depending on the size and quantity ordered. Several domestic suppliers of ceramic foam filters are available in India, making it easier for foundries to source these filters locally.

Future of the Indian Casting Industry

The Indian casting industry has enormous growth potential, supported by favorable government policies, skilled labor, and technological advancements. The industry is expected to grow at a compound annual growth rate of 7.3%, reaching a production level of 16.3 million tons by 2025.

In conclusion, the Indian casting industry is a promising sector with significant opportunities for growth in the future. With the right policies and investments in modern technology and skilled labor, the industry can overcome the challenges it faces and emerge as a global leader in casting production. The pricing of ceramic foam filters in India is competitive, offering foundries reliable options for filtering molten metal and producing high-quality castings.