The casting and foundry industry plays a pivotal role in shaping modern manufacturing processes. Ensuring the quality and integrity of casted products is of paramount importance, and this is where “Ceramic Foam filters” come into play. However, the journey of importing these crucial components into Uzbekistan from China is fraught with challenges, reflecting the significance of ceramic foam filters for casting industry.

The Significance of Ceramic Foam Filters for Casting Industry

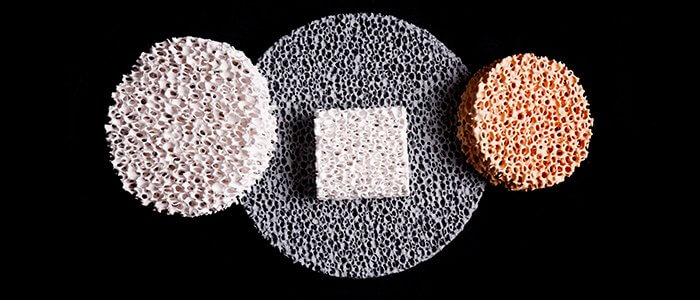

Ceramic Foam filters are specialized components designed to filter out impurities from molten metals during casting processes. These filters exhibit a unique cellular structure that enables them to capture contaminants, ensuring that the final casted products are free from defects and possess optimal mechanical properties. As such, they are indispensable tools for maintaining casting quality and efficiency.

The Demand for Ceramic Foam Filters in the Casting Industry

In the casting and foundry industry, the quality of the end product is directly linked to the quality of the materials and processes involved. Even a minor impurity or contamination in the molten metal can lead to defects such as porosity, inclusions, and poor surface finish in the final casted product. These defects compromise the integrity and mechanical properties of the product, rendering it unsuitable for its intended application.

Ceramic Foam filters address this issue by efficiently removing impurities before the molten metal solidifies. As a result, the casting industry has recognized these filters as essential components to ensure consistent product quality and performance. Their significance cannot be overstated, as the industry strives to meet stringent quality standards and customer expectations.

Challenges of Importing Ceramic Foam Filters from China to Uzbekistan

While the demand for Ceramic Foam filters in Uzbekistan’s casting industry is high, the process of importing them from China presents several difficulties:

Logistical Challenges: The physical distance between China and Uzbekistan can lead to extended shipping times, potential delays, and increased transportation costs. Ensuring the timely arrival of Ceramic Foam filters becomes a logistical puzzle that importers must navigate.

Customs and Import Regulations: Importing goods involves adhering to complex customs and import regulations. Ensuring compliance with these regulations, including tariffs and documentation requirements, adds an additional layer of complexity to the process.

Language and Communication Barriers: Effective communication between Chinese suppliers and Uzbekistani importers is vital for successful transactions. Language barriers and differences in business practices can hinder smooth negotiations and order processing.

Quality Assurance: The casting industry relies on consistent quality to produce reliable products. Importing Ceramic Foam filters from China necessitates establishing trust in the supplier’s quality control practices and ensuring that the filters meet the required specifications.

Currency Fluctuations and Payment Methods: Currency fluctuations can impact the overall cost of importing, affecting budgeting and financial planning. Moreover, selecting secure and convenient payment methods while considering exchange rates adds another layer of complexity.

Conclusion

Ceramic Foam filters are critical components for the casting and foundry industry, ensuring the production of high-quality casted products. Importing these filters from China to Uzbekistan is a process laden with challenges, ranging from logistical issues to regulatory hurdles. However, the importance of these filters for maintaining product quality, integrity, and customer satisfaction makes overcoming these challenges imperative.

The casting industry in Uzbekistan’s pursuit of excellence must grapple with these difficulties to ensure a consistent supply of Ceramic Foam filters. Collaborative efforts between importers, suppliers, and regulatory authorities are essential to streamline the import process and support the growth of Uzbekistan’s casting industry.