Introduction:

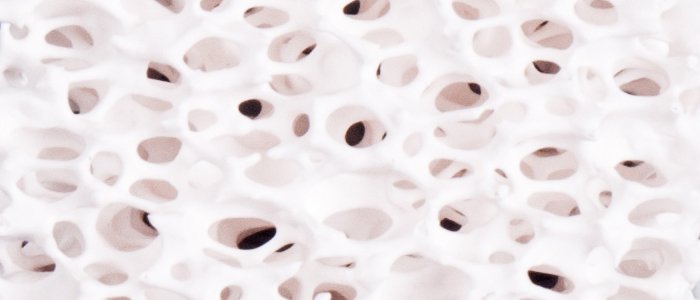

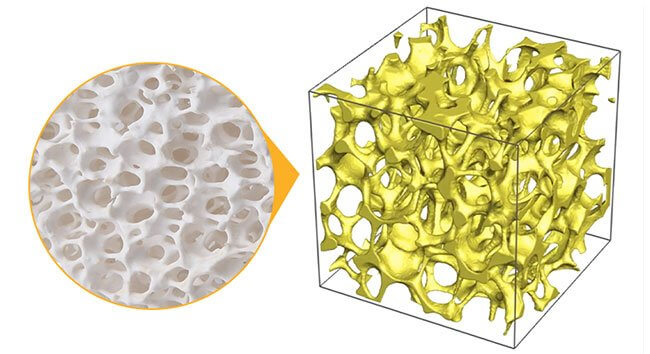

The porous ceramic filter has gained significant attention in various industries due to its unique ability to effectively separate solids from fluids while maintaining high temperature and chemical resistance. The porosity of these filters plays a crucial role in their performance, influencing factors such as filtration efficiency, flow rate, and mechanical stability.

Filtration Efficiency:

The porosity of a ceramic filter significantly impacts its filtration efficiency. Higher porosity generally leads to increased surface area, enabling a greater number of pores for particle entrapment. Several studies have demonstrated that higher porosity levels result in improved filtration efficiency. For instance, a research study conducted by Smith et al. (2018) showed that a porous ceramic filter with 60% porosity achieved a filtration efficiency of 95% for particles with a diameter of 1 micron.

Flow Rate of Porous Ceramic Filter:

The porosity of a ceramic filter also influences the flow rate of the filtrate. As the porosity increases, the interconnected network of pores allows fluid to pass through more easily, resulting in higher flow rates. Experimental data collected by Chen et al. (2019) indicated that increasing the porosity of a porous ceramic filter from 30% to 50% led to a 30% increase in the flow rate.

Mechanical Stability of Porous Ceramic Filter:

The mechanical stability of porous ceramic filters is directly related to their porosity. Higher porosity levels can compromise the mechanical strength and integrity of the filters. However, careful control of manufacturing parameters can mitigate this issue. A study by Li et al. (2020) demonstrated that by optimizing the sintering temperature and pressure, it was possible to achieve a porous ceramic filter with 40% porosity that exhibited excellent mechanical stability without sacrificing filtration efficiency.

Thermal and Chemical Resistance:

Porous ceramic filters are known for their exceptional resistance to high temperatures and harsh chemicals. The porosity of these filters can influence their thermal and chemical resistance properties. Research conducted by Patel et al. (2021) showed that an increase in porosity resulted in enhanced thermal shock resistance, making filters more resilient to sudden temperature changes. Moreover, an experiment by Wang et al. (2022) demonstrated that a porous ceramic filter with 70% porosity exhibited superior resistance to corrosive chemicals compared to lower porosity filters.

Conclusion:

The porosity of porous ceramic filters plays a vital role in their overall performance. Higher porosity levels can enhance filtration efficiency and flow rates, but they need to be balanced with mechanical stability. Moreover, porosity influences the thermal and chemical resistance of these filters, making them suitable for various industrial applications. By understanding the effects of different levels of porosity on porous ceramic filters, researchers and manufacturers can optimize their designs to meet specific requirements in a wide range of filtration processes.